Understanding Press Brake Types and Their Industrial Applications Hydraulic press brakes: Power and reliability for heavy-duty fabrication In industrial fabrication shops across the country, hydraulic press brakes stand out as essential tools when ...

VIEW MORE

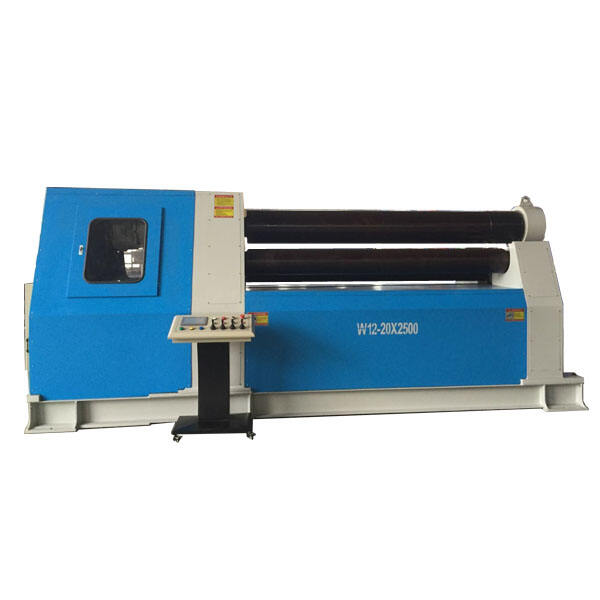

How CNC Plate Rolling Machines Enhance Precision and Efficiency in Metal FormingThe Role of CNC Technology in Automating Metal Sheet BendingCNC tech has really changed how we bend metal sheets these days. Instead of relying on old school methods, it ...

VIEW MORE

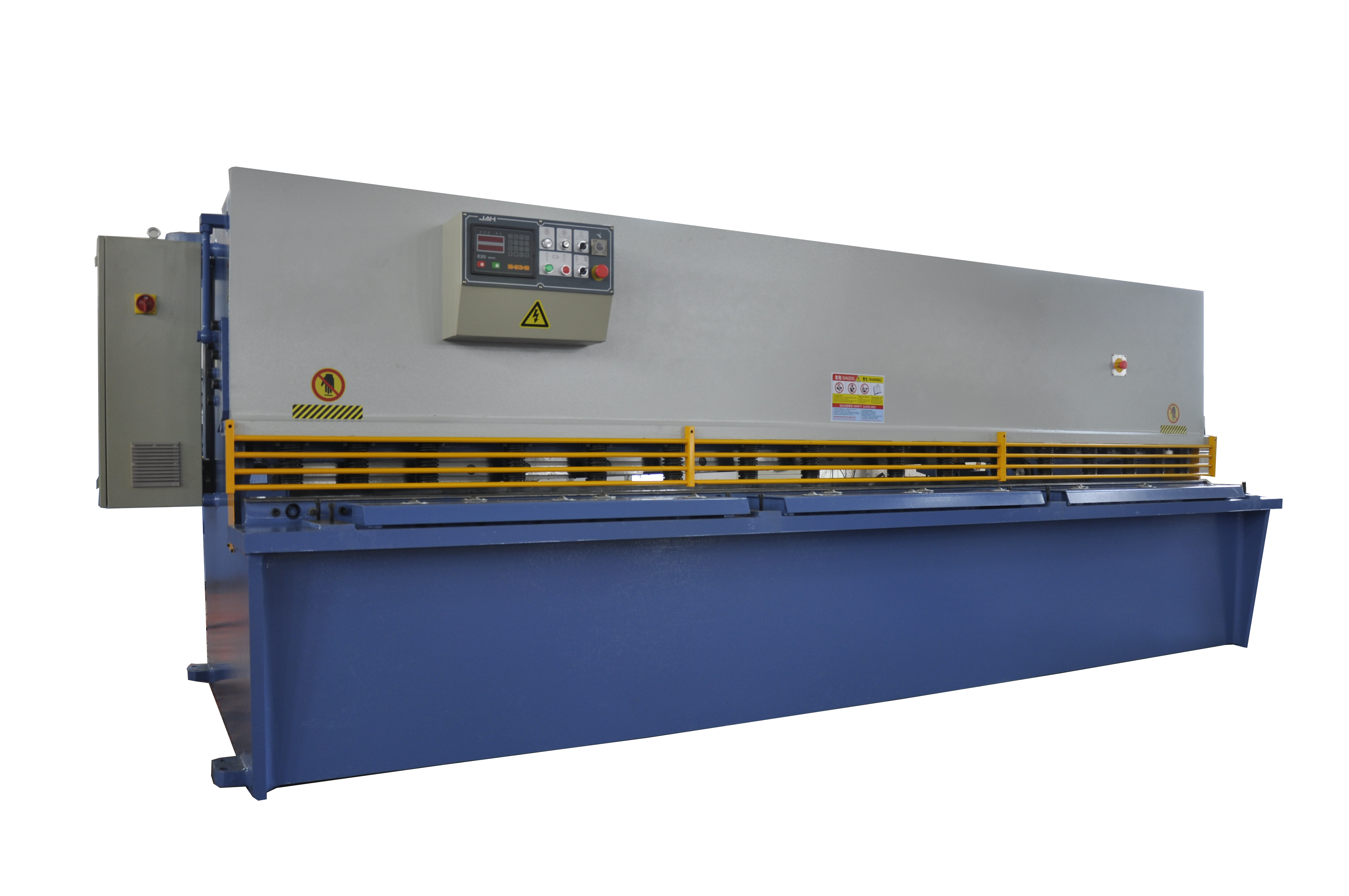

Pre-Operation Safety Checks for Guillotine Shearing Machines Identifying Common Hazards Associated with Guillotine Shearing Machines Most accidents with guillotine shears happen because of sharp blades, moving parts sticking out, or problems with t...

VIEW MORE

Understanding Operational Stress and Failure Mechanisms in Plate Bending Rolls How Plate Bending Rolls Degrade Over Time The plate bending rolls tend to break down over time because of constant rubbing, repeated stress loads, and just plain old metal...

VIEW MORE

What Is a Press Brake and Its Role in Metal Fabrication? Definition and primary function of press brakes in metalworking The press brake stands as one of those critical machines used for bending sheet metal accurately through controlled application ...

VIEW MORE

How Guillotine Shearing Machines Work: Mechanism and Key Components The guillotine mechanism explained: Applying force for clean, precise cuts A guillotine shear works by moving an upper blade down vertically against a stationary lower blade to sli...

VIEW MORE

How Press Brakes Work: Principles of Force, Tooling, and Bending Understanding the Basic Function of a Press Brake Press brakes work by shaping metal sheets when they apply just the right amount of pressure using specially aligned tools. These mach...

VIEW MOREUnderstanding Hydraulic Press Forming Requirements Assessing Material Compatibility Evaluating material compatibility is crucial when selecting a hydraulic press for forming operations. Metals like steel and aluminum are commonly used in hydraulic pr...

VIEW MORE

Understanding Plate Bending Rolls and Their Mechanics What Are Plate Bending Rolls? What Are Plate Bending Rolls? Plate bending rolls (or rolling machines) are among the most critical pieces of equipment for bending steel plate into a specific radiu...

VIEW MORE

Integration of Hydraulic and CNC Technologies Evolution of Hydraulic Systems in Guillotine Shears The performance of guillotine shears was greatly improved with the help of hydraulic systems through the years. Guillotine Shear's initial des...

VIEW MORE

Types of Roll Bending Machines for Small BusinessesHydraulic Plate Bending Machines: Durability and AffordabilityHydraulic plate bending machines are a robust choice for small businesses due to their durability and cost-effectiveness. These machines ...

VIEW MORE

Understanding Heavy-Duty Plate Rolling Machines 3-Roll vs. 4-Roll Plate Rolling Machines It’s important to know the differences between 3-roll and 4-roll machines. The two systems are obviously based on different mechanisms for efficientl...

VIEW MORE