Integration of Hydraulic and CNC Technologies

Evolution of Hydraulic Systems in Guillotine Shears

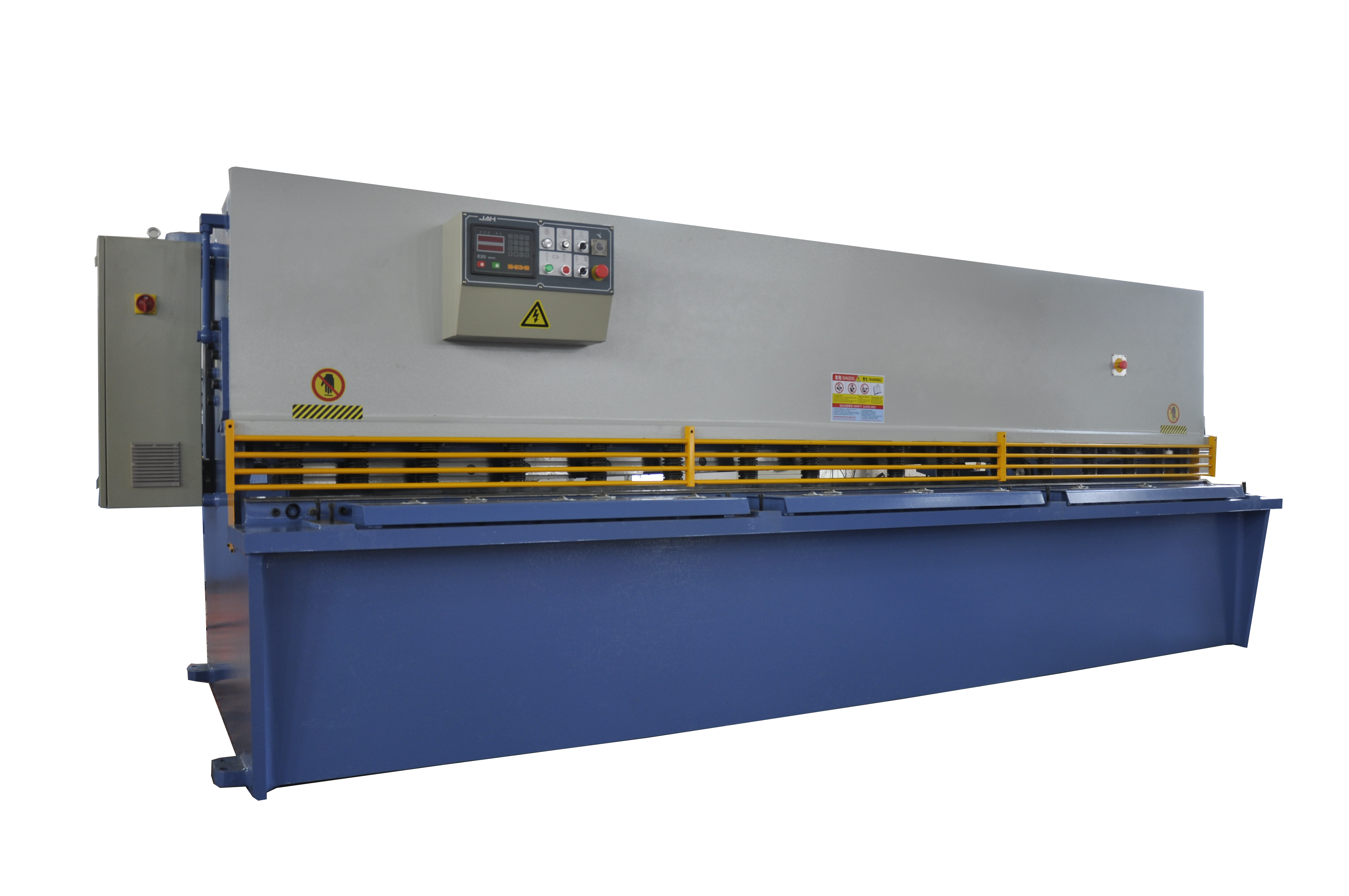

The performance of guillotine shears was greatly improved with the help of hydraulic systems through the years. Guillotine Shear's initial designs were mechanical processes that are not only inefficient, but inflexible. By embedding hydraulic systems, key technological breakthroughs â such as pressure control and increased cutting force efficiency â were brought to life, redefining metal cutting. Today, metal hydraulic shearing machines are more quick and energy efficient, so they are more widely used in modern enterprises. For instance, some hydraulic models offer up to 30 percent faster cutting speeds – which can bring notable productivity increases. Historical examples, like the evolution of hydraulic shearing machines, show that innovations like automated pressure calibration can lead to smoother, quicker operations, leading to higher output.

Role of CNC Controls in Precision Cutting

The application of Computer Numerical Control (CNC) technology in guillotine shearing machine is a significant factor in the realization of accurate cutting. With the help of CNC control systems precise adjustments as well as intergrated feedback systems to further optimize the cutting process for greater accuracy can be realized. The stated accuracy in CNC guillotine shearing machines has been proved to be much higher than the tolerances of conventional methods and can certainly be said to be as good as nil or closer to nil and so on. That kind of accuracy prevents materials waste, which is absolutely vital for economical manufacturing, and also means a higher quality final product. In addition, CNC technologies ensure greater control over the cut parameters, resulting in much more consistently and efficiently meeting the specs of the manufacturer.

Synchronization with Plate Bending Machinery

Synchronization of hydraulic system in guillotine shears with plate bending machine is required to arrange fully automated manufactories. Accordingly, such coordination between operations has been known to allow for increased efficiencies in those processes, e.g., reduced set-up times, increased material handling, etc. In the past this has been proven through case studies but it can be seen that where hydraulic plate bending machinery is correctly synchronised with guillotine shears, there are far less bottlenecks in the production process. Synchronization to technical standards, such as digital communicationprotocols, is useful in this context. The outcome is a sleeker workflow, which means the production line becomes both more efficient and more scalable, and manufacturers are able to deliver increased production without a decrement in quality or speed.

Advances in Automation and Smart Features

IoT-Enabled Guillotine Shearing Machines

The inclusion of the Internet of Things (IoT) in guillotine cutters bring maintenance monitoring and predictive analytics into the next generation and allows access to smarter operations. Because these machines are connected in the IoT, you can collect data in real time, which can help minimize downtime by both generating predictive maintenance notifications and diagnostics. According to Industry Week, manufacturing companies are able to predict when equipment will fail and therefore maintain higher levels of operational productivity. Reducing downtime means better productivity and a better bottom line. The LVD Group is among the companies that have successfully implemented IoT capabilities, improving operational efficiency and providing critical data on machine condition and performance. This development reflects a trend towards increasingly technology-advanced, connected and automated production environments.

AI-Driven Process Optimization

Guillotine shearing machine uses intelligent analysis and adaptation in cutting process, artificial intelligence (AI) optimizes cutting parameters and advances cycle times. Through patterns and variables detection AI detect possible improvements to win in procesess and performs to a more efficient way while lowering costs. An example of a case study that Manufacturing Tomorrow shared shows how AI-enhanced operations led to a 20% reduction in cycle times and substantial cost savings. These applications do not only optimize processes but inform future trends in which AI integration is has the potential to become a standard in manufacturing environments. Thanks to new technologies like machine learning algorithms, manufacturers are now equipped to harness the power of AI for greater accuracy and speed.

Integration with Press Brake Systems

In applications to which a press brake and hydraulic shear can be integrated, there is a rise in the usage of guillotine shears in conjunction with press brake systems for adaptable manufacturing solutions and increased material handling efficiency. The integration allows them to switch from cutting to bending operations without any downtime, which results in shorter setup times and greater material handling capacities. Trumpf had a successful application of this kind that demonstrated that synchronizing guillotine shears with press brake systems resulted in well-organized production lines and an expanded production range. The advantages of such fusion are reflected in an improved versatility by which the technology can be personalized and applied in manufacturing to meet different industry demands. This trend highlights the necessity of integrating technologies to enable an agile and responsive manufacturing environment, which is essential to tackling the changing demands of the market.

Enhanced Precision and Material Compatibility

Cutting High-Strength Alloys with Improved Blades

The development of the blade has enabled hydraulic metal shear machine to process moderate and high strength alloy quickly. Also, manufacturers have come up with state-of-the-art blades that are wear resistant hence cost-effective. So, for example, such advanced blades have a longer life span, resulting in less frequent replacement and less associated downtime costs. High-strength alloy cutting is increasingly requested in the automotive and aerospace industry, where durable parts under high temperature and pressure are needed. These industries take advantage of the accuracy and reliability in cutting performance of latest blade technology.

Adaptive Gap Adjustment for Thin-to-Thick Plates

With the rapid development of technology, mechanical CNC armed shears were born, and the CNC guillotine shearing machine also has a very practical adjustable gap function. This flexibility results in almost no waste and increased productivity when cutting thinner plates as well as thicker plates. This feature, according to research findings, can increase efficiency by over 15% due to the removal of manual recalibration. The leading manufacturers, particularly those in the area of precision engineering, have integrated these features into their products to create items that are second to none in regards to their flexibility and accuracy, which has revolutionised the production of a range of different metal-based products.

Compatibility with Rolled Metal Forms

The compatibility of hydraulic plate bending machine with rolled shapes metals is vital to realize functional flexibility and widen productization aspect. This interchangability allows the machines to process an extensive variety of rolled shapes, necessary in the construction and machinery manufacturing sector. For instance, vendors who fully embrace the technology that guarantees such compatibility may be able to deliver more sophisticated product portfolios, as well to take advantage of additional business. Machines equipped with certain technical capabilities, such as the adjustable rollers and the strong structural forms, allow the different shapes to be compatible and abundant in the production, thus enhancing the flexibility of the equipment.

Sustainable Manufacturing Practices

Energy-Efficient Hydraulic Power Units

The guillotine shearing machine hydraulic power unit with energy saving has brought a new blood into the operation of hydraulic cutting machines and achieved the intent of power saving. These systems feature cutting edge technology which makes energy consumption efficient and saves a whole lot of money. For instance, early adopters in manufacturing have, claimed energy cost savings that can exceed 20%, and lend birth to potential cost savings and operational efficiency throughout the industry”. In addition to reducing operating costs, such enhancements support larger sustainability initiatives. These metal shearing press among hydraulic shearing machines for metal lowers energy expectations and fosters an environment-friendly operation, a plus in a world that's increasingly concerned about greener processes.

Recyclable Component Design Trends

The production industry is increasingly adding recyclable elements to guillotine shearing machine parts, in a bid to reduce the environmental footprint. The reuse and recycling of materials is also making its comeback with this trend, decreasing wastage going into landfills. Quality suppliers such as producers of three roll plate bending machines, are setting the standard for these responsible design techniques, with waste consumption being drastically curtailed. For example, in some cases there has been a 30% reduction in production waste stemming from recycling of parts. Moreover, such developments symbolize a greater sense of corporate responsibility while also making the product more appealing to consumers who are now more prone to buying from eco friendly companies. The acceptance of recyclable components is emerging as one of the signatures of sustainability in contemporary manufacturing.

Noise-Reduction Innovations

Advancements in sound reduction are the cause of hydraulic guillotine shears that are becoming increasingly more user-friendly and currently conforms to industry regulations. Equipped with the latest in noise reduction technology, these systems provide a quiet working environment by reducing noise levels in industrial applications. The proven effect of these technologies is also evidenced across multiple case studies in other applications, where operators have experienced less noise-induced stress and higher workplace productivity. Vibration dampening systems and noise-reduced enclosures are also becoming more popular. Innovations in hydraulic press brake machines are not only raising operator comfort to new levels, they’re also meeting tightening workplace noise regulations in a commitment to both new thinking and employee well-being.

Safety Innovations and Ergonomic Design

Laser Safety Guards and Sensor Technology

Safety guards with sensors on the hydraulic metal shear spreader take operator security to a new level. These may detect obstacles and automatically stop the machine, reducing the risk of injury. In the absence of these features, operator mishaps use to occur quite a bit. For instance, some factories experienced 40% fewer accidents after they implemented sensor-based safety technologies. ISO 13849 and other industry standards promote advanced safety features, highlighting the need for these kinds of technologies. Most applications require periodic verification and calibration of the system for best performance and maximum workplace safety.

Operator-Friendly Interface Developments

The latest innovations in operator interfaces for CNC guillotine shears have done much to ease use and optimise the production process. Time and MTTR have been greatly reduced with the uses of innovations including touch-screen controls and simpler software layouts. Research shows that with such easy to use interface can reduce operator errors by 30% and GR8ly increase productivity. Companies like Amada and Trumpf have been at the forefront of ergonomic design programs to ensure that their machines are both efficient and a pleasure to use. The progress represents the sectorâs determination to develop machines that are how user friendly as they are safe.

Automated Scrap Removal Systems

The use of robotic scrap-handling systems is also making a significant contribution towards improving safety by minimizing the need for operators to handle the often sharp scrap that falls from hydraulic plate bending machines. These mechanisms allow for expedited garbage delivery and helps to prevent cuts and other safety hazards. Efficiency and safety of up to 25% are reported in the use of automated systems where human error in scrap handling is eliminated. The author forsees that, in the future, these systems will be further evolved thanks to the progress of robotics and artificial intelligence, increasing their effectiveness from both a safety and operational point of view. The next generation of automated scrap handling will offer even more for safety systems and machine efficiency.