Types of Roll Bending Machines for Small Businesses

Hydraulic Plate Bending Machines: Durability and Affordability

Hydraulic plate bending machines are a robust choice for small businesses due to their durability and cost-effectiveness. These machines can handle various metal thicknesses and types, thanks to their sturdy construction and powerful hydraulic systems. Unlike CNC models, hydraulic machines often require a lower initial investment, making them highly attractive to small business owners with budget constraints. The simplicity of the hydraulic mechanism offers substantial force for bending without complex technology, allowing operators to easily learn and use the equipment. According to industry analysis, businesses adopting hydraulic models can see a notable increase in productivity since these machines are reliable and easy to maintain. This makes hydraulic plate bending machines an ideal investment for small enterprises that prioritize both performance and affordability.

CNC Plate Bending Machines: Precision for Small-Scale Operations

For small-scale operations that require precision, CNC plate bending machines are the go-to option. These machines provide unmatched accuracy and repeatability, essential for projects with specific design requirements. CNC technology allows for programming multiple bending sequences, significantly reducing production time and increasing output. Though they demand a higher upfront investment, the long-term benefits cannot be overlooked, such as lower labor costs and material waste, which enhance profitability. Industry experts suggest that companies using CNC machines can achieve precision tolerances of ±0.5 mm or better, making these machines indispensable for businesses focusing on high-quality, customized products. By deploying CNC machines, small businesses can meet their precision needs and optimize their production processes.

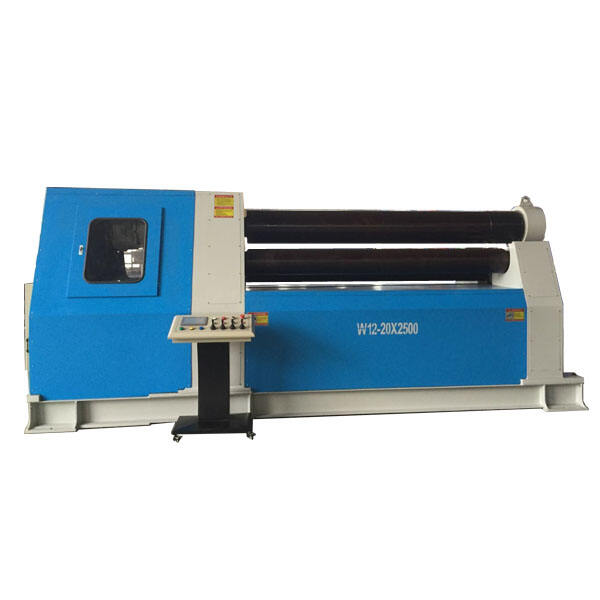

Heavy-Duty Plate Rolling Machines: Balancing Power and Cost

Heavy-duty plate rolling machines strike a balance between power and affordability for small businesses looking to handle larger projects. These machines come equipped with powerful motors and high torque capabilities, allowing them to process thicker materials efficiently. However, business owners must carefully select the appropriate model, as higher capacity machines may lead to elevated costs and operational expenses. When appropriately loaded, well-reviewed heavy-duty machines can result in a 30% decrease in job turnaround times, making them a competitive edge for businesses aiming to enhance productivity. These machines are a sound investment for enterprises that require a powerful solution to tackle demanding metal bending tasks without compromising their budget.

Key Features for Cost-Effective Roll Bending

Evaluating Initial Costs vs. Long-Term Value

When considering roll bending machines, it's vital to balance initial purchasing costs against long-term operational and maintenance expenses. Initially, investing in high-quality machines might seem costly, but the benefits include reduced repair needs and minimal downtime. Over time, these savings can offset initial expenses significantly. One effective approach is creating a detailed cost-benefit analysis model, which highlights potential savings over periods like five years, thereby helping businesses make informed investment decisions.

Energy Efficiency in Hydraulic and CNC Models

Energy efficiency is a critical factor when choosing between hydraulic and CNC roll bending machines, particularly amidst rising energy costs. Newer models are designed to be energy-efficient, potentially lowering monthly utility bills by up to 25%. It's worth exploring the various features offered by manufacturers, such as automatic shutdowns and energy monitoring systems, to maximize these savings. Investing in energy-efficient models not only contributes to cost savings but also promotes environmental sustainability.

Importance of Modular Press Brake Parts

Utilizing modular press brake parts can be strategically advantageous for businesses looking to customize and enhance their machines without undergoing complete overhauls. This flexibility in upgrading components proves invaluable as new technologies emerge, allowing businesses to extend their equipment's lifespan and improve functionality. Additionally, opting for parts from reputable manufacturers ensures reliability, minimizing maintenance costs and downtime. Thus, modular components offer a cost-effective path to maintaining cutting-edge machinery while controlling operational expenses.

Maximizing Value: Maintenance and Lifespan Tips

Routine Care for Hydraulic Systems

Regular maintenance of hydraulic systems is crucial for ensuring efficient operation and prolonging the lifespan of your machine. By routinely checking hydraulic fluid levels and replacing filters, you can prevent significant malfunctions and reduce unexpected repair costs. These tasks, ideally performed quarterly, are simple yet effective in minimizing downtime and maintenance expenses. Ensuring these checks are part of your regular maintenance schedule for your hydraulic plate bending machines can notably enhance longevity and reliability.

Preventing Wear in Heavy-Duty Rollers

To extend the life of heavy-duty rollers, due diligence in maintenance can prevent significant wear and tear. Regular application of appropriate lubrication is key in mitigating friction and wear, which helps prolong their functionality. Encouraging operators to perform daily inspections for signs of damage or wear can also preempt potential issues, thereby avoiding costly repairs and operational interruptions. Through such proactive measures, heavy duty plate rolling machine maintenance becomes more predictable and cost-effective.

Upgrading Components for Long-Term Savings

Investing in the upgrade of components such as dies and blades can drastically enhance the performance and efficiency of bending machines. High-quality upgrades not only improve machine output by as much as 20%, as supported by various studies, but they also lead to reduced energy consumption. In the long term, these enhancements result in substantial savings and improve product quality, making a compelling case for regular component upgrades.

Where to Source Budget-Friendly Roll Bending Machines

Trusted Manufacturers like Nantong Yeshun

When sourcing budget-friendly roll bending machines, partnering with renowned manufacturers like Nantong Yeshun is a prudent choice. These manufacturers are known for delivering reliable and high-quality machines, backed by solid post-purchase support. Studies indicate that machines from reputable brands often incur lower service and repair costs owing to superior manufacturing standards. This not only ensures that the machines run efficiently and have a longer lifespan, but also offers peace of mind with comprehensive customer support. Trustworthy manufacturers are key in maintaining operational stability and cost-effectiveness over time.

Evaluating Refurbished or Entry-Level CNC Models

Exploring refurbished CNC models can be a cost-effective strategy for businesses, especially those just starting out or operating on a tight budget. Refurbished machines provide substantial savings while still offering commendable performance levels, akin to their brand-new counterparts. It's vital, however, to scrutinize these options by checking for warranties, which can offer reassurance about the machine's operational condition and durability. Such warranties can act as a safety net, mitigating the risk of future breakdowns and ensuring continued productivity without unexpected costs.

Marketplaces for Cost-Effective Heavy-Duty Machines

Online and local marketplaces are treasure troves for budget-savvy acquisitions of heavy-duty machines. Platforms like eBay and Craigslist are popular among many businesses for finding economically viable options. However, success in these ventures often hinges on building strong relationships with sellers. Trust and rapport can lead to significant discounts or negotiate better terms, making the purchasing process both cost-effective and transparent. Thus, engaging with marketplaces offers not only variety but also potential financial advantages through strategic negotiations.