Reduced Material Waste in Laser Cutting Operations

How Laser Cutting Minimizes By-Products

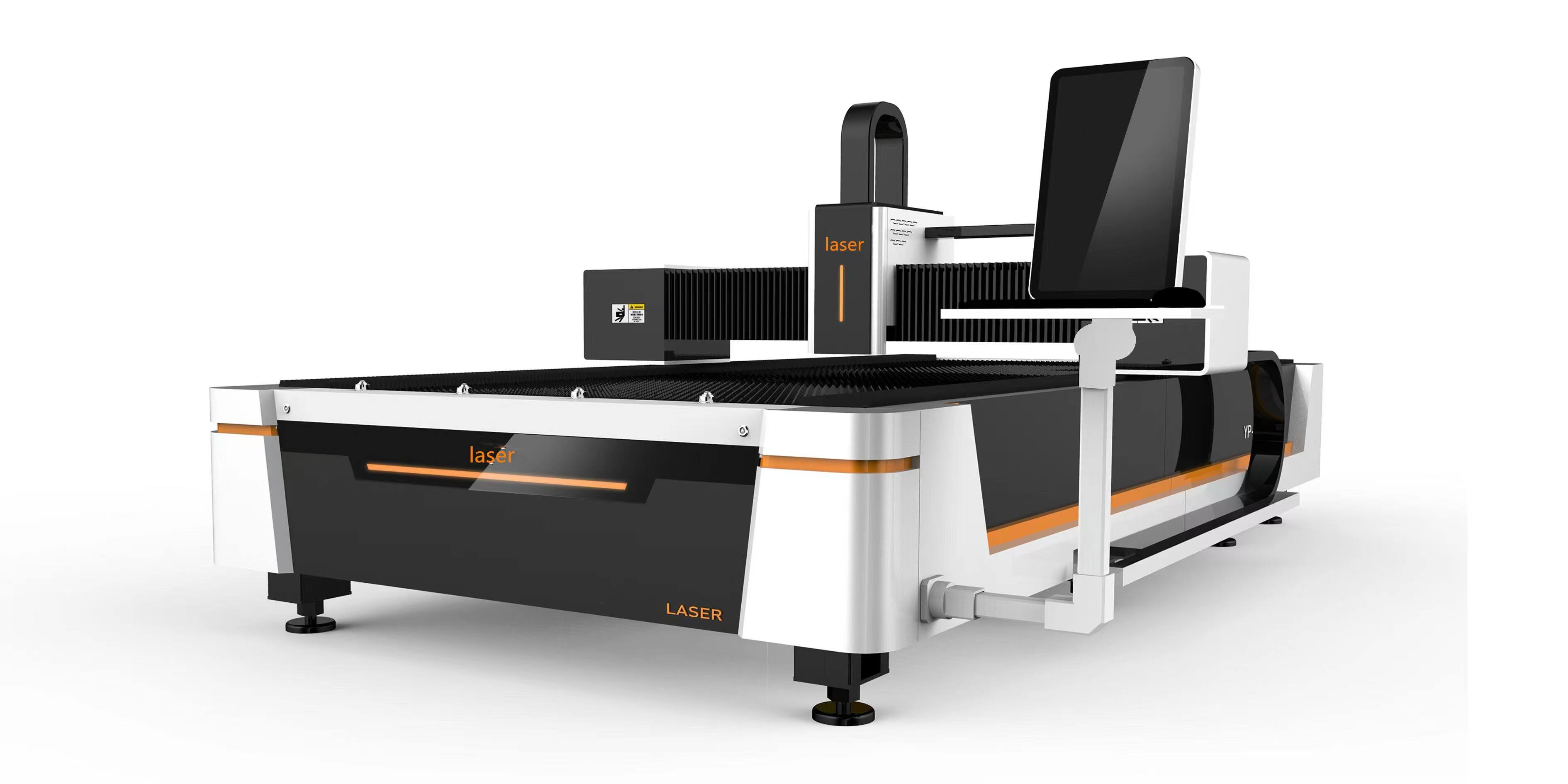

Laser cutting technology is pivotal in reducing scrap material compared to traditional methods. It employs a precise energy application method that allows for cleaner cuts, which substantially reduces by-products. Thanks to the high-intensity laser beam, the need for additional trimming or reworking diminishes, leading to enhanced efficiency. Studies reveal that laser cutting can reach material utilization rates of up to 90%, contingent on the complexity of the cut shapes. This not only preserves resources but also significantly cuts down on disposal costs, showcasing its eco-friendly advantages.

Optimized Material Usage Through CNC Technology

CNC technology enhances laser cutting by optimizing layout designs to effectively minimize waste. With the use of advanced algorithms, CNC systems can orchestrate the most efficient means to nest parts on a material sheet, thus maximizing resource utilization. Reports from industries employing CNC laser cutting systems, such as CNC guillotine shearing machines, show up to a 30% reduction in material waste over traditional methods. By investing in such equipment, businesses can enjoy sustainable practices through versatile and resource-efficient operations.

Energy Efficiency and Lower Carbon Footprint

Comparing Energy Consumption: Lasers vs. Traditional Machinery

Laser cutting systems are renowned for their energy efficiency, particularly when compared to traditional machinery such as hydraulic press brake machines. These laser systems demand significantly less energy, with data indicating they can use up to 50% less energy than their conventional counterparts. This stark reduction not only decreases operational costs but also results in a smaller carbon footprint, making it a sustainable choice for manufacturers. The energy efficiency of laser cutting is further pronounced due to its quick cycle times and minimal downtime when compared to older methods. This advantage allows businesses that transition to laser technology to realize significant savings in their energy bills over time, effectively aligning with sustainability objectives.

Sustainable Power Sources for Laser Systems

To further reduce environmental impacts, integrating renewable energy sources like solar and wind into laser cutting operations is a forward-thinking strategy. Investing in energy-efficient laser systems that are adaptable to sustainable power setups can significantly boost energy performance. Indeed, utilizing renewable power in laser cutting processes has been shown to drop operational greenhouse gas emissions by as much as 70%. This transition aligns seamlessly with global sustainability strategies while also enhancing a company's reputation as a green innovator. Companies prioritizing eco-friendly practices by adopting these energy-efficient methods not only contribute positively to environmental stewardship but also stand to gain from a solid brand image as leaders in sustainability.

Precision Engineering for Eco-Conscious Production

Eliminating Secondary Processing Through Accuracy

Laser cutting technology has revolutionized precision engineering, significantly reducing the need for secondary processes. This high level of accuracy allows manufacturers to conserve both energy and materials, which are crucial for eco-conscious production. By minimizing additional machining steps, manufacturers can lower operational costs and accelerate production timelines. Studies highlight that achieving tight tolerances on the first cut enhances overall manufacturing efficiency.

Producing components that meet specifications right from the first cut not only saves time but also minimizes waste. The precision of laser cutting directly contributes to reduced operational waste, aligning perfectly with eco-conscious manufacturing practices. As such, laser technology plays a pivotal role in creating more sustainable production processes by eliminating unnecessary resource expenditure.

Laser Cutting vs Conventional Metal Fabrication Equipment

Environmental Impact of Hydraulic Press Brakes

Hydraulic press brakes consume significant amounts of energy and generate high levels of noise and waste, making them less environmentally friendly compared to laser cutting. The operation of hydraulic systems can lead to emissions and potential leakages, posing environmental hazards. In contrast, laser cutting operates pollution-free, with a cleaner and more efficient process that minimizes the carbon footprint of manufacturing. Lifecycle assessments of laser cutting equipment reveal not only lower emissions but also a smaller overall environmental impact. As regulatory standards increasingly demand reduced emissions, utilizing laser technologies meets these requirements, positioning them as a sustainable choice in modern manufacturing environments.

Advantages Over Three Roll Plate Rolling Machines

Three roll plate rolling machines often present limitations in size and versatility compared to the flexibility of laser cutting. Laser cutting technology allows for precise handling of various materials and complex shapes, which reduces material waste and eliminates deformities often associated with traditional rolling methods. Businesses adopting laser systems can benefit from smaller, more efficient machine setups, optimizing space and reducing energy consumption. Furthermore, the agility of laser cutting systems to quickly adapt between tasks enhances workflow efficiency, offering significant advantages over the traditional slow and rigid processes associated with three roll plate rolling machines.

Applications Driving Sustainable Manufacturing

Automotive Industry Case Studies

In the automotive industry, laser cutting has revolutionized manufacturing processes, making them more sustainable and efficient. Multiple case studies highlight how laser cutting has significantly reduced scrap material and energy use during production. For instance, companies that have integrated laser technologies report measurable decreases in waste, which directly contributes to their environmental and economic goals. Assembly lines equipped with laser cutting systems experience enhanced operation speeds and customization capabilities, allowing for precise modifications that meet diverse customer demands. Adopting laser cutting is not merely a trend but a necessity for automotive manufacturers aiming to achieve sustainability goals.

Architectural Metalwork With Minimal Waste

Laser cutting stands out in architectural metalwork by enabling designs with minimal waste, a critical factor in modern eco-friendly design standards. Its precision allows for intricate patterns to be crafted without sacrificing material strength or design integrity. Projects employing laser cutting report reduced surface damage and superior end-product quality, aligning well with architects' eco-conscious goals. Notably, the accuracy inherent in laser systems ensures that even complex patterns are executed flawlessly, promoting responsible resource usage in the construction industry. These achievements in laser cutting foster a culture of sustainability and encourage more projects to adopt eco-friendly manufacturing practices.