The Role of Laser Cutting Machines in Modern Surgical Instrument Manufacturing

Micron-Level Precision for Life-Saving Tools

Laser cutting machines offer an unmatched level of precision essential for the manufacturing of surgical instruments, which often require exact measurements to function effectively in delicate procedures. This capability is especially crucial in healthcare, where even a minor deviation can have life-or-death consequences. The remarkable precision of laser machines allows them to cut at a micron-level, surpassing the thickness of a human hair, thereby reducing the risk of instrument malfunction. Such precision is vital in creating tools for surgeries and implants, where accuracy ensures the intended medical outcomes. According to industry studies, surgical instruments manufactured through laser cutting have a significantly lower failure rate compared to those made using traditional methods.

Speed and Consistency in High-Stakes Production

In high-demand fields such as healthcare, speed and consistency in production cannot be overemphasized. Laser cutting machines not only enhance production speed, enabling manufacturers to meet these high demands, but they do so without compromising quality. The technology ensures each surgical instrument is made with the same high standards, which is essential for maintaining the trust of medical professionals and patients alike. Moreover, reports indicate that using laser technology in manufacturing settings can boost production rates by up to 30%. This increase is vital for healthcare systems, allowing them to efficiently deliver necessary tools and devices, thereby improving overall healthcare delivery and effectiveness.

Types of Laser Cutting Machines Transforming Medical Manufacturing

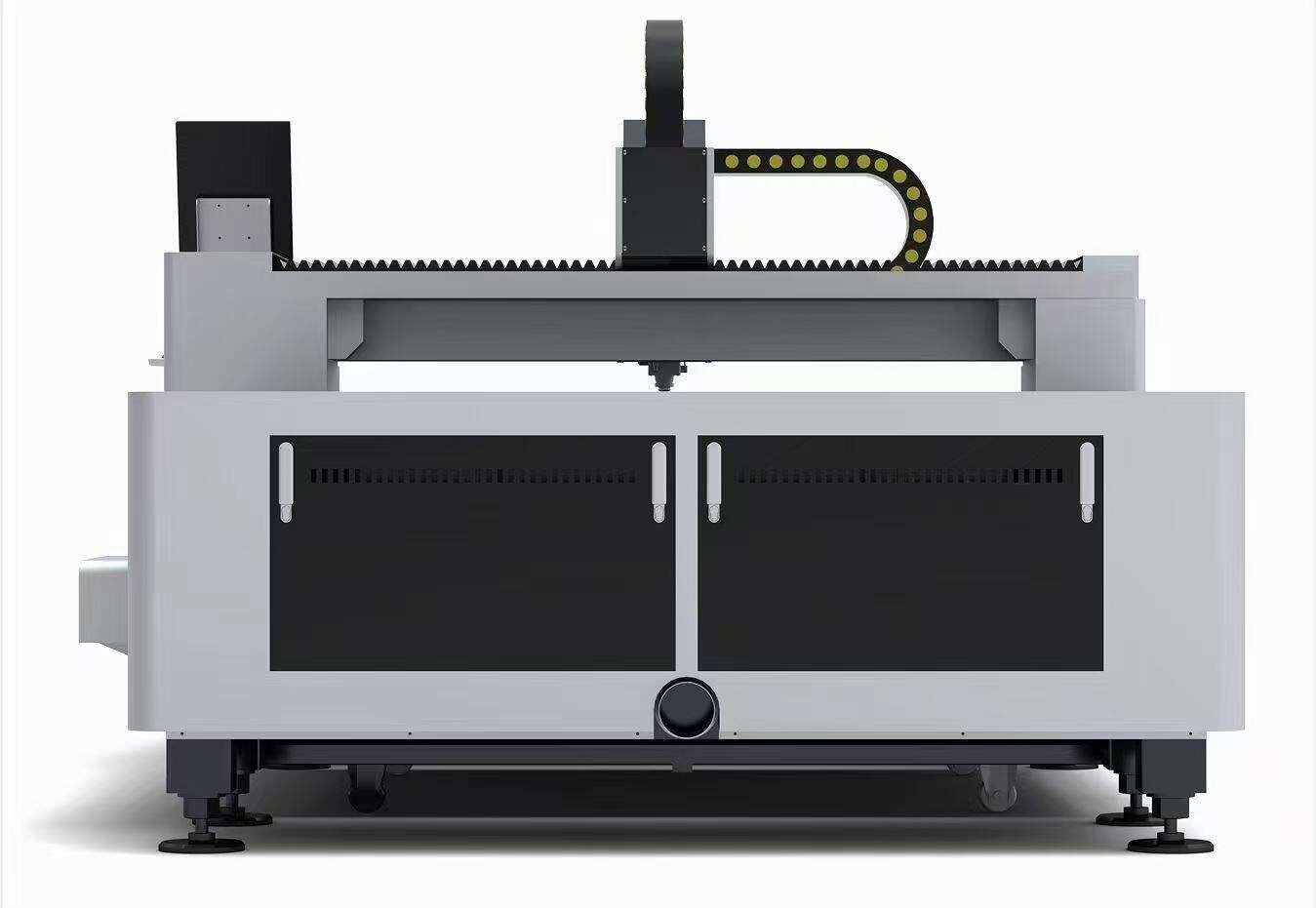

Fiber Laser Cutting Machines: Efficiency in Metal Processing

Fiber laser cutting machines are transforming surgical instrument manufacturing due to their efficiency in metal processing. These machines stand out because they provide superior speed and power, facilitating the detailed designs often necessary for complex surgical tools. For instance, the ability of fiber lasers to operate at up to 80% efficiency ensures maximum material utilization and minimal waste. This efficiency not only reduces costs but also improves production throughput, making it easier to meet the stringent demands of the medical industry. Industry data further supports these claims, highlighting the capability of fiber lasers in enhancing both productivity and precision in creating life-saving tools.

CO2 Laser Cutting Machines: Versatility for Polymers and Soft Metals

CO2 laser cutting machines are highly versatile, famed for their ability to handle a variety of materials, including polymers and soft metals. This adaptability is crucial for medical manufacturers striving to produce diverse surgical instruments tailored to multiple applications. The versatility of CO2 lasers has significantly impacted production advantages, evidenced by a reported 25% increase in the range of surgical instruments these machines can create. This flexibility ensures that healthcare institutions have access to a wider selection of tools necessary for various medical procedures, enabling better patient care and operational efficiency.

UV Lasers: Micro-Machining for Miniaturized Components

UV lasers are gaining prominence in the medical manufacturing sector for their role in micro-machining tiny components crucial to modern surgical instruments. Specifically designed for precision work, these lasers create miniaturized parts with low heat impact, preserving material integrity and ensuring the safety of surgical devices. Research shows that UV lasers significantly boost the accuracy of micro-components, making surgical tools safer and more effective. By facilitating intricate cuts and designs, UV lasers play a pivotal role in advancing minimally invasive surgeries, thus contributing to innovative medical procedures and improved patient outcomes.

Key Applications in Surgical Instrument Production

Cardiovascular Stents: Intricate Patterns for Blood Flow Optimization

Laser cutting technology is crucial for forming intricate patterns in cardiovascular stents, which are essential for optimizing blood flow. The precision offered by lasers ensures that these patterns are not only intricately detailed but also safely designed for implantation within the body. This high level of precision is necessary as minor discrepancies could lead to complications. Studies in healthcare have shown that stents crafted using advanced laser technology significantly enhance patient outcomes, underscoring the importance of laser precision in medical manufacturing. By leveraging lasers, manufacturers can produce stents that not only meet design specifications but also improve patient care and reduce the risk of complications over time.

Orthopedic Implants: Customizable Titanium and Cobalt-Chrome Designs

The customization of orthopedic implants has been revolutionized by laser cutting technology, allowing for implants made from titanium and cobalt-chrome to be tailored to each patient's anatomy. This customization improves the fit and comfort of the implants, leading to better surgical results and faster recovery. The ability to precisely cut these metals helps in creating implants that conform to patient-specific requirements, enhancing functionality. Data from the industry shows that these customized implants result in a 30% reduction in revision surgeries. This statistic highlights how significant laser cutting technology is in producing reliable and efficient orthopedic solutions tailored for individual patients.

Minimally Invasive Surgical Tools: Precision for Laparoscopic Devices

Minimally invasive surgical tools, such as laparoscopic devices, demand the highest precision levels, which are met efficiently by laser cutting machines. These tools, designed for operating through small incisions, benefit from the reduced size that laser technology affords, thus promoting quicker recovery times post-surgery. The precision of laser cutting ensures that these devices work effectively and consistently, which is crucial for the success of minimally invasive surgeries. Surgeons often stress the importance of laser-driven precision in enhancing the overall performance and reliability of these instruments, which, in turn, contributes to superior patient outcomes in minimally invasive procedures.

Advantages Driving Adoption in Healthcare Manufacturing

Non-Contact Process: Reducing Contamination Risks

The non-contact process of laser cutting technology significantly reduces the risks of contamination in surgical instrument manufacturing. By eliminating the need for physical touch, laser cutting minimizes the potential for introducing pathogens during production. This is vital in healthcare where sterility and cleanliness are paramount. Healthcare studies have shown that instruments manufactured through non-contact methods are less likely to harbor contaminants, ensuring a safer end product. This approach not only improves cleanliness but also translates into enhanced patient safety, making it a crucial technique in the production of surgical instruments.

Material Versatility: From Biocompatible Metals to Bioresorbable Polymers

Laser cutting machines offer unparalleled versatility by efficiently processing various materials from biocompatible metals like titanium to bioresorbable polymers. This capability is crucial in medical applications, allowing for the adaptation to diverse surgical needs through innovative treatments and designs. Research indicates a 20% increase in production efficiency in facilities utilizing these machines for a wide range of materials, showcasing their efficiency. This material flexibility supports the crafting of highly specialized medical devices, enhancing both the design and the functional scope of healthcare solutions.

Automated Quality Control for Regulatory Compliance

Incorporating automated quality control in laser cutting processes ensures compliance with stringent medical regulations, crucial for healthcare manufacturing. These systems guarantee that each instrument adheres to the highest standards, averting costly recalls and potential legal issues. Statistics reveal that facilities implementing such quality checks have seen a reduction of over 40% in compliance-related incidents. This automation underscores the reliability and consistency of laser cutting machines, making them integral in the medical field where precision and safety are non-negotiable requirements.

Future Trends in Medical Laser Cutting Technology

Integration with 3D Printing for Patient-Specific Implants

The integration of laser cutting with 3D printing marks a significant advancement in medical manufacturing, particularly in the development of patient-specific implants. This synergy enables the creation of highly customized implants that perfectly fit individual anatomical structures, enhancing the effectiveness of surgical procedures. By tailoring implants to each patient's unique needs, recovery times can be improved, and outcomes can be optimized. As we look to the future, the trend towards personalized medical solutions is expected to accelerate, with 3D printing and laser cutting becoming commonplace technologies in producing custom medical devices.

AI-Powered Laser Systems for Real-Time Adjustments

AI-powered laser systems are setting the stage for transformative changes in precision manufacturing by enabling real-time adjustments during the cutting process. This technological innovation enhances precision, reduces errors, and assures improved product quality, aligning with stringent manufacturing standards. The capability of AI systems to adapt and optimize cutting conditions dynamically means that facilities can ensure regulatory compliance more efficiently. Predictions in the industry suggest that AI integration will become a standard practice in high-precision manufacturing sectors, including medical device production, within the next decade. This advancement holds promise for higher safety standards and finer quality in medical devices.

Sustainable Manufacturing with Energy-Efficient Lasers

The focus on sustainable manufacturing practices has positioned energy-efficient laser technologies at the forefront of the medical manufacturing industry. These advanced laser systems allow manufacturers to maintain high cutting quality while significantly reducing power consumption, thus contributing to lower operational costs. As the industry continues to prioritize sustainability, initiatives geared towards energy-efficient machinery are expected to drive a considerable shift in medical manufacturing practices. Industry forecasts highlight the importance of environmental responsibility, predicting a substantial increase in the adoption of sustainable laser technologies in medical device production, enhancing both economic and environmental outcomes.

Table of Contents

- The Role of Laser Cutting Machines in Modern Surgical Instrument Manufacturing

- Types of Laser Cutting Machines Transforming Medical Manufacturing

- Key Applications in Surgical Instrument Production

- Advantages Driving Adoption in Healthcare Manufacturing

- Future Trends in Medical Laser Cutting Technology