How Laser Technology Transforms Design Concepts into Prototypes

Laser technology operates on the principle of using focused light beams to make precise cuts through various materials, thus transforming complex designs into tangible prototypes with remarkable accuracy. The main advantage of this method is rapid prototyping, which significantly reduces the time-to-market and enhances the speed of iterations—an essential factor for keeping up with fast-paced market demands. Industries such as automotive and aerospace particularly benefit from rapid prototyping through laser cutting as it allows them to swiftly advance from design to functional prototypes. This acceleration is supported by industry reports indicating that laser cutting can reduce prototype creation times by over 50% compared to traditional methods. This technology enables not just speed but also precision manufacturing, allowing companies to refine and test their designs effectively. Utilizing laser technology transforms the prototyping phase from a bottleneck into a streamlined process, ensuring products are market-ready in record time.

Material Versatility: Metals, Plastics, and Beyond

Laser cutting boasts incredible material versatility, as it can effectively cut through a wide range of substances, including an assortment of metals, diverse plastics, and even composite materials. Different laser technologies, such as fiber lasers and CO2 lasers, are optimized for specific materials, with fiber laser cutting machines being particularly adept at cutting metals, while CO2 lasers excel with plastics and non-metal materials. This adaptability not only broadens the scope of potential prototypes but also leads to substantial material savings and waste reduction, making laser cutting an economically attractive option. According to statistics, implementing laser cutting technology can reduce material wastage by up to 30%—an impressive figure that demonstrates its efficiency. The precise nature of laser cutting eliminates unnecessary wastage by delivering cuts that adhere closely to design specifications, ensuring that material is used optimally. By choosing the right laser for the right material, industries can leverage this technology for both prototyping and full-scale production without compromising on quality or sustainability.

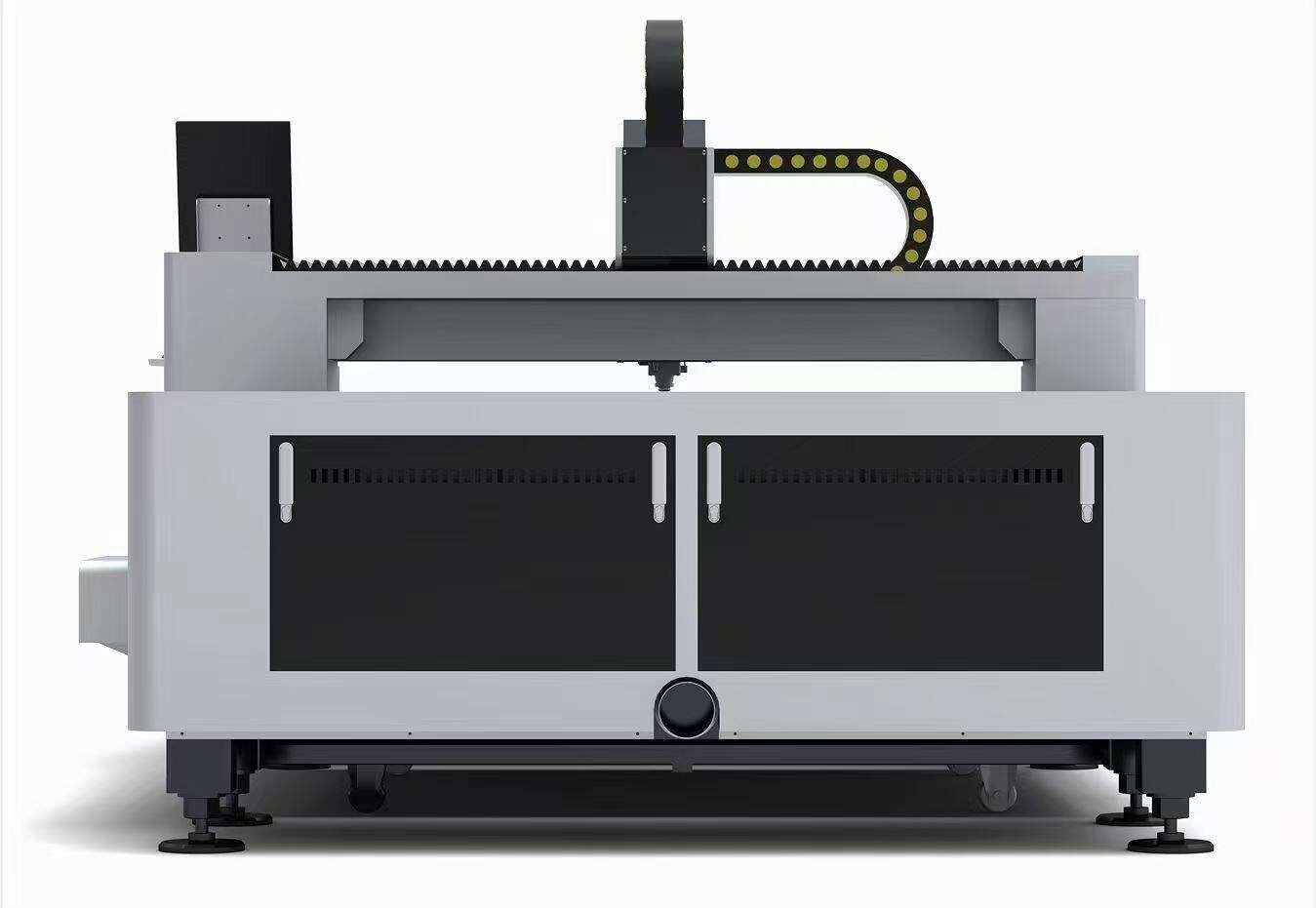

## Fiber vs. CO2 Laser Cutters: Choosing the Right MachineFiber Laser Cutting Machines: Precision for Metal Prototyping

Fiber laser cutting machines are renowned for their unparalleled precision and efficiency, particularly when it comes to metal prototyping. These machines utilize a fiber optic cable to amplify light, focusing it into a high-intensity beam that can seamlessly slice through metals with exceptional accuracy. One of the most significant advantages of fiber lasers over CO2 lasers is their higher efficiency and comparatively lower operational costs. Fiber lasers require less power to operate, making them more energy-efficient and cost-effective in the long run. Case studies from leading manufacturers highlight the improved outcomes achieved with fiber lasers; for instance, the reduction in processing time and enhanced precision have allowed companies to streamline their prototyping processes, delivering high-quality metal prototypes efficiently. This makes fiber lasers an invaluable asset in metal prototyping, setting new standards for speed and accuracy in precision cutting.

CO2 Laser Cutting Machines: Flexibility for Complex Designs

CO2 laser cutting machines are lauded for their flexibility, particularly in handling non-metal materials and crafting intricate designs. They employ a gas mixture to generate the laser beam, which is effective in cutting through a diverse array of materials such as plastics, wood, and textiles. This versatility makes CO2 lasers ideal for industries like arts and crafts, signage, and complex design layouts, where a range of materials and precise cuts are required. Industry experts often cite the adaptability of CO2 systems, emphasizing their broad application potential in various domains. The ability to execute delicate and complex cuts with precision makes CO2 laser cutters a popular choice when working on detailed projects requiring more than just metal cutting. Therefore, for businesses valuing flexibility and creativity in design, CO2 laser machines stand out as a versatile and reliable choice.

## Scaling Up: Laser Cutting in Mass Production WorkflowsSpeed and Consistency in High-Volume Manufacturing

Laser cutting technology significantly enhances both speed and consistency in high-volume manufacturing. By incorporating laser cutting machines into production lines, manufacturers can reduce human error and produce consistent outputs, which is essential for maintaining quality standards in mass production environments. For instance, studies show that integrating laser cutters can increase production output by up to 30% when compared to traditional methods. This impressive improvement is largely due to the automated nature of laser technologies, which allow for precise and repeatable cuts without the need for manual intervention. Furthermore, the role of automation plays a crucial part; it not only boosts efficiencies but also reduces the reliance on skilled labor, ensuring that operations can be scaled without compromising on quality.

Integrating with Hydraulic Press Brakes for Finished Products

The integration of laser cutting machines with hydraulic press brakes offers a robust workflow for creating finished products. This combination allows manufacturers to efficiently fabricate high-quality components by leveraging the precision of laser cutting for initial shaping, followed by the forming capabilities of hydraulic press brakes. This synergy streamlines the workflow, enabling seamless product development with minimal material handling between stages. Companies that have adopted this integrated approach report increased efficiency and reduced production times, especially in industries that demand precision and finished quality, such as the automotive and aerospace sectors. The workflow integration ensures that both technologies work in tandem, providing a coherent and efficient manufacturing process that maximizes productivity and ensures superior end products.

## Real-World Applications of Laser Cutting VersatilityCase Study: Rapid Prototyping for Automotive Accessories

In the automotive sector, laser cutting has revolutionized the rapid prototyping process for accessories. One notable case study involves a leading automotive company that integrated fiber laser cutting machines into their design and production workflows. This integration facilitated faster prototyping and refinement cycles, leading to improved designs and quicker product launches. The precision of laser cutting allowed for intricate designs that were previously unachievable with traditional methods, effectively speeding up production times by nearly 30%. Moreover, the cost of prototyping was reduced significantly due to the minimal material wastage and efficient use of resources. These advancements highlight how laser cutting can drive innovation and efficiency in automotive accessory development.

Medical Shield Production During Supply Chain Crises

The adaptability of laser cutting technology was most evident during recent supply chain crises, particularly in the production of medical shields. Laser cutting machines played a critical role in rapidly manufacturing these essential items when demand spiked unexpectedly. The rapid turnaround time and precision offered by CO2 laser cutting machines ensured that medical shields could be produced swiftly, meeting urgent healthcare needs. Testimonials from medical supply organizations underscored the technology's pivotal role, stating that production speed increased by 40% during peak crisis periods. This response showcased the versatility and reliability of laser cutting technology in times when quick adaptation was necessary to safeguard lives.

## Optimizing Laser Cutting Processes for Industrial DemandsBalancing Power Consumption with Cutting Efficiency

In recent years, advancements in laser cutting technology have significantly improved cutting efficiency while reducing power consumption. These efforts are critical given the global push towards sustainable manufacturing practices. For instance, modern fiber laser cutting machines are designed to minimize energy usage while maintaining high-precision cuts, a feature particularly valuable for industrial needs. Studies have quantified these benefits, showing a reduction in power consumption by up to 30% when optimized systems are implemented. This equates to substantial cost savings and a reduced environmental footprint for manufacturing operations.

Maintenance Strategies for Continuous Production

Ensuring continuous production in laser cutting operations is vital, and effective maintenance strategies are key to achieving this goal. Companies often implement best practices such as scheduled routine checks and prompt repairs to prevent unexpected downtimes. These strategies not only extend the lifespan of machines like CO2 and fiber laser cutting machines but also mitigate production losses. Reports have demonstrated that proactive maintenance can reduce machine downtimes by an estimated 20%, thereby enhancing productivity and ensuring the timely completion of projects.

Table of Contents

- How Laser Technology Transforms Design Concepts into Prototypes

- Material Versatility: Metals, Plastics, and Beyond

- Fiber Laser Cutting Machines: Precision for Metal Prototyping

- CO2 Laser Cutting Machines: Flexibility for Complex Designs

- Speed and Consistency in High-Volume Manufacturing

- Integrating with Hydraulic Press Brakes for Finished Products

- Case Study: Rapid Prototyping for Automotive Accessories

- Medical Shield Production During Supply Chain Crises

- Balancing Power Consumption with Cutting Efficiency

- Maintenance Strategies for Continuous Production