W12 hydraulics plate rolling machine with 4 rolls W12-30x3200

A four-roll plate bending machine is an advanced industrial equipment designed for precision bending of metal sheets into cylindrical, conical, or arc-shaped components. Compared to traditional three-roll machines, its four-roll configuration (comprising two upper rolls and two lower rolls) ensures superior control, reduced material waste, and enhanced efficiency.

Description

4 rolls Hydraulic plate bending machine with double pre-bending.

Useful length from 1000mm to 6000mm.

Thickness from 2 up to 100mm.

With our four rolls plate bending machine,plate can be bent on both side without return.Full automatic controlled by PLC,there’s no need for additional processing steps for bending the ends.The flat edge is 1.5-2 times of the thickness.

Quality certificate such as CE and ISO9001.

Key Features & Advantages:

- High Precision: The four-roll system minimizes plate slippage and eliminates the need for pre-bending edges, ensuring consistent curvature and smooth surfaces.

- Automated Operation: Equipped with CNC (Computer Numerical Control) systems, it allows programmable adjustments for complex bending tasks.

- Material Versatility:Capable of handling various metals (steel, stainless steel, aluminum, etc.) with wide thickness and width ranges.

- Energy Efficiency: Reduced idle rolling and optimized workflow lower operational costs.

- End-to-End Forming: The dual lower rolls grip the plate securely, enabling complete bending without repositioning.

Applications:

Widely used in industries such as shipbuilding, pressure vessels, wind towers, pipelines, and structural steel fabrication.

Technical Parameters (Example):

- Bending Thickness: 6–150 mm (varies by model)

- Maximum Plate Width: Up to 6000 mm

- Roll Diameter: Customizable for material rigidity

- Control System: Hydraulic-driven with CNC

This machine is ideal for heavy-duty industrial applications requiring high productivity and repeatable accuracy.

Product Details

Specification:

• Pinch roll and lateral rolls move with hydraulic pistons in orbital way;

• Top roll powered by hydro-motor

• Hydraulic drop end for easy removal of finished ferrule

• Easy operation with mobile control panel

• Welded steel frame

• Induction hardened rolls(42CrMo)

• Hydraulic balance system

• Overload protection

Standard component:

• Movable control panel

• Hardened rolls

• Digital read out for both rolls

• Hydraulic station

• Hydraulic motor

• Hydraulic drop end

• Cone bending device

Optional equipment

• Top and lateral support rack for big diameter

• Ground and polished rolls for special job

• Safety cable

• Fan cooled or water cooled

Spare parts brand

NO. |

Main Machine part |

Technical Requirement |

|

|

1 |

Working roller |

Material |

42 CrMo |

|

Techniques |

Forging piece go through rough machining then quenching and tempering treatment at HB241~280 |

||

Finish turning then medium frequency quenching of surface at HRC40-45 | |||

|

2 |

Side Frame and Chassis |

Material |

42 CrMo |

|

Techniques |

Side Roller Lift Cylinder Material for 45# forgings, quenching and tempering heat treatment HB217-255. |

||

Fixed and tipping side frame and chassis are welding pieces of steel plate | |||

3 |

Drive Device |

Motor |

Hanzhu,Ningbo |

|

4 |

Control Device |

Low Voltage Apparatus |

Siemens,Germany |

|

5 |

Hydraulic System |

Pump Station |

ChangYuan,China Options: Sunny,USA |

Valve |

Yuken,Japan |

||

6 |

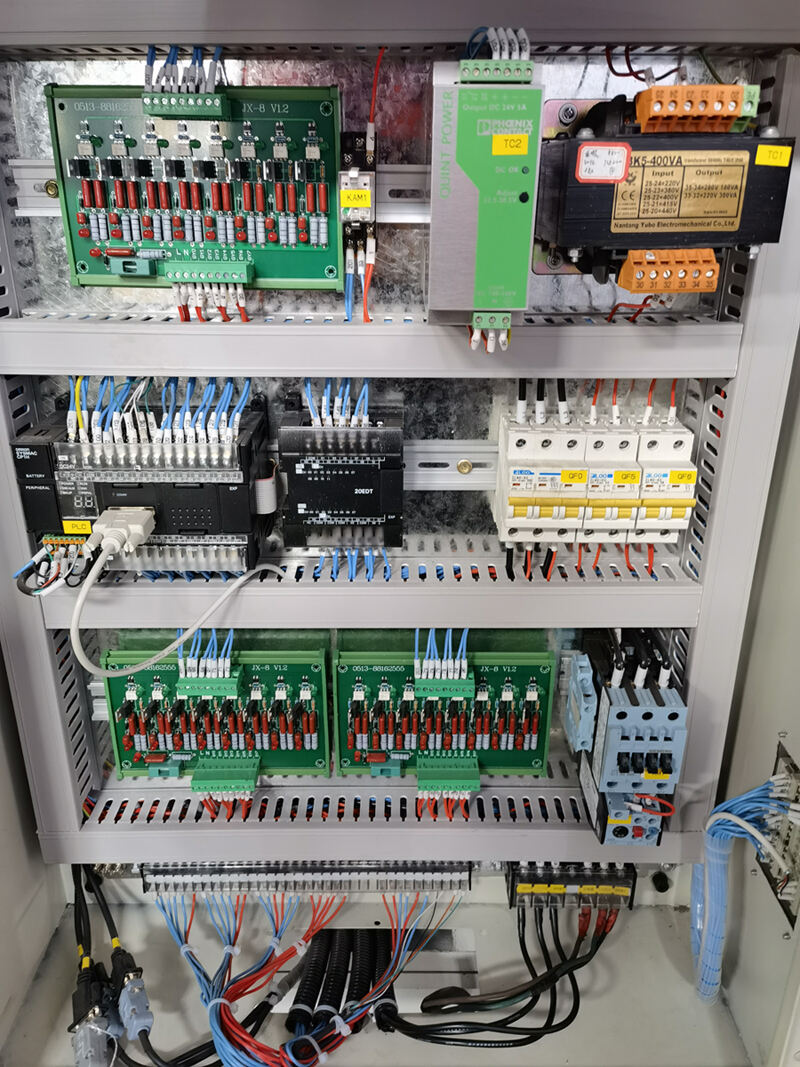

Electrial Control System |

Touchwin from China |

|

7. |

Sealings |

Nok from Japan |

|

8. |

Bearing |

WFD |

|

9. |

PLC Encoder |

Omron from Japan |

|

10. |

Other Electrical Parts |

Siemens from Germany |

|

Parameter sheet

Model |

Max. Bending thickness(mm) |

Pre-bending thickness(mm) |

Max. Working length of rolls(mm) |

Yield limit (Mpa) |

Top roller diameter(mm) |

Lower roller diameter(mm) |

Side roller diameter(mm) |

Main power (KW) |

W12-4x2000 |

4 |

3.5 |

2050 |

245 |

160 |

140 |

120 |

3 |

W12-6x2000 |

6 |

5 |

2050 |

245 |

190 |

170 |

150 |

4 |

W12-8x2000 |

8 |

6.5 |

2050 |

245 |

210 |

190 |

170 |

5.5 |

W12-10x2000 |

10 |

8 |

2050 |

245 |

230 |

210 |

190 |

7.5 |

W12-12x2000 |

12 |

10 |

2050 |

245 |

270 |

250 |

210 |

11 |

W12-16x2000 |

16 |

13 |

2050 |

245 |

300 |

270 |

220 |

11 |

W12-20x2000 |

20 |

16 |

2050 |

245 |

330 |

300 |

240 |

11 |

W12-25x2000 |

25 |

20 |

2050 |

245 |

360 |

330 |

250 |

15 |

W12-30x2000 |

30 |

25 |

2050 |

245 |

390 |

360 |

300 |

18.5 |

W12-35x2000 |

35 |

28 |

2050 |

245 |

430 |

390 |

330 |

22 |

W12-40x2000 |

40 |

32 |

2050 |

245 |

460 |

420 |

360 |

30 |

W12-45x2000 |

45 |

36 |

2050 |

245 |

510 |

460 |

390 |

37 |

W12-50x2000 |

50 |

40 |

2050 |

245 |

550 |

510 |

420 |

45 |

W12-4x2500 |

4 |

3.5 |

2550 |

245 |

190 |

170 |

150 |

4 |

W12-6x2500 |

6 |

5 |

2550 |

245 |

210 |

190 |

170 |

5.5 |

W12-8x2500 |

8 |

6.5 |

2550 |

245 |

230 |

210 |

190 |

7.5 |

W12-10x2500 |

10 |

8 |

2550 |

245 |

270 |

250 |

210 |

11 |

W12-12x2500 |

12 |

10 |

2550 |

245 |

300 |

270 |

220 |

11 |

W12-16x2500 |

16 |

13 |

2550 |

245 |

330 |

300 |

240 |

11 |

W12-20x2500 |

20 |

16 |

2550 |

245 |

360 |

330 |

250 |

15 |

W12-25x2500 |

25 |

20 |

2550 |

245 |

390 |

360 |

300 |

18.5 |

W12-30x2500 |

30 |

25 |

2550 |

245 |

430 |

390 |

330 |

22 |

W12-35x2500 |

35 |

28 |

2550 |

245 |

460 |

420 |

360 |

30 |

W12-40x2500 |

40 |

32 |

2550 |

245 |

510 |

460 |

390 |

37 |

W12-45x2500 |

45 |

36 |

2550 |

245 |

550 |

510 |

420 |

45 |

W12-4x3000 |

4 |

3.5 |

3100 |

245 |

210 |

190 |

170 |

5.5 |

W12-6x3000 |

6 |

5 |

3100 |

245 |

230 |

210 |

190 |

7.5 |

W12-8x3000 |

8 |

6.5 |

3100 |

245 |

270 |

250 |

210 |

11 |

W12-10x3000 |

10 |

8 |

3100 |

245 |

300 |

270 |

220 |

11 |

W12-12x3000 |

12 |

10 |

3100 |

245 |

330 |

300 |

240 |

11 |

W12-16x3000 |

16 |

13 |

3100 |

245 |

360 |

330 |

250 |

15 |

W12-20x3000 |

20 |

16 |

3100 |

245 |

390 |

360 |

300 |

18.5 |

W12-25x3000 |

25 |

20 |

3100 |

245 |

430 |

390 |

330 |

22 |

W12-30x3000 |

30 |

25 |

3100 |

245 |

460 |

420 |

360 |

30 |

W12-35x3000 |

35 |

28 |

3100 |

245 |

510 |

460 |

390 |

37 |

W12-40x3000 |

40 |

32 |

3100 |

245 |

550 |

510 |

420 |

45 |

W12-50x3000 |

50 |

40 |

3100 |

245 |

610 |

560 |

480 |

55 |

W12-60x3000 |

60 |

48 |

3100 |

245 |

670 |

620 |

520 |

75 |

Company Profile

Nantong Yeshun Machinery Manufacture Co., Ltd. was established in 2003, located in the advanced industrial city--Haian. It's a professional manufacture of metal plate processing equipment such as plate rolling machine and profile bending machine, press brake, guillotine shearing machine and laser cutting machine, etc.

In recent years, we have absorbed foreign advanced technology, research and developed series CNC products with independent intellectual property rights and international advanced level. We have more than a dozen varieties type of plate rolling machine and profile bending machine(W12 CNC four rolls plate bending machine, W11 three rolls symmetrical plate bending machine, W11F asymmetrical plate bending machine, W11S heavy duty upper universal plate bending machine, W11H arc adjust plate bending machine, W24S full hydraulic profile bending machine, WYQ24 semi-hydraulic profile bending machine,etc.), WC67Y(K) press brake, QC11Y(K) guillotine shear, laser cutting machine, hydraulic press, ironworker and other models.

Besides, our factory has a complete set of well-known processing equipment with advanced technology and high precision, and strictly implements the ISO9001 quality system standard, which has laid a solid foundation for the production of high-quality products. All products produced by the factory have independent and experienced before-sales and after-sales service to better satisfy the customer’s needs throughout the world.