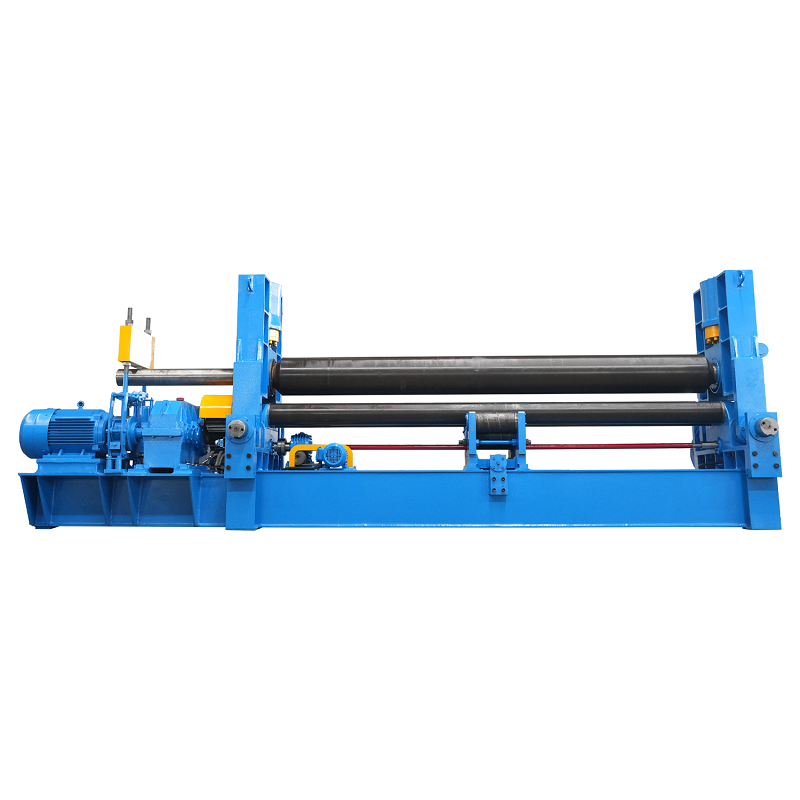

W11S upper roller universal plate rolling machine W11S-10×2500

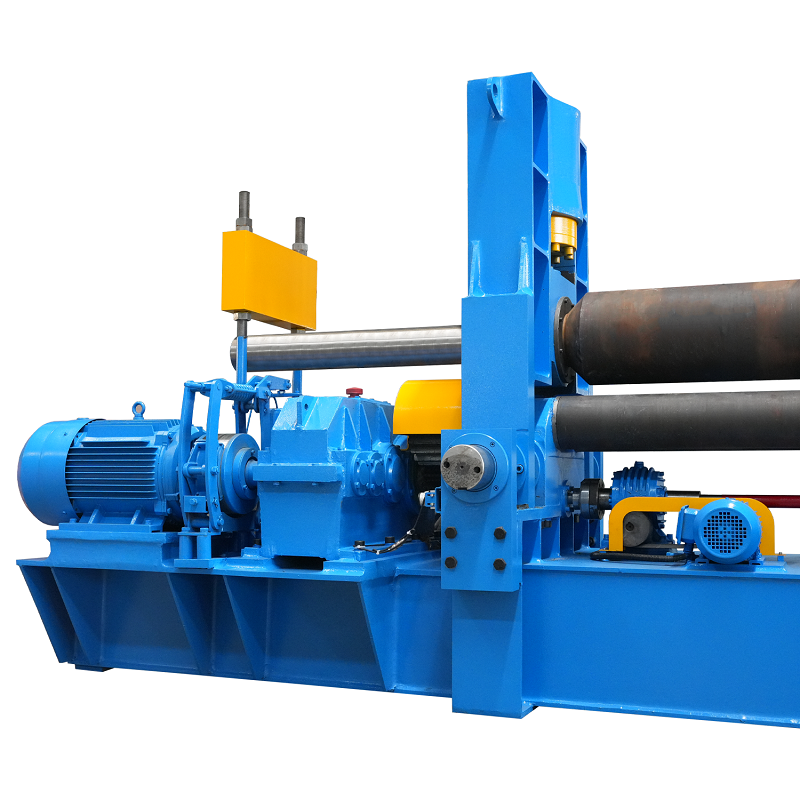

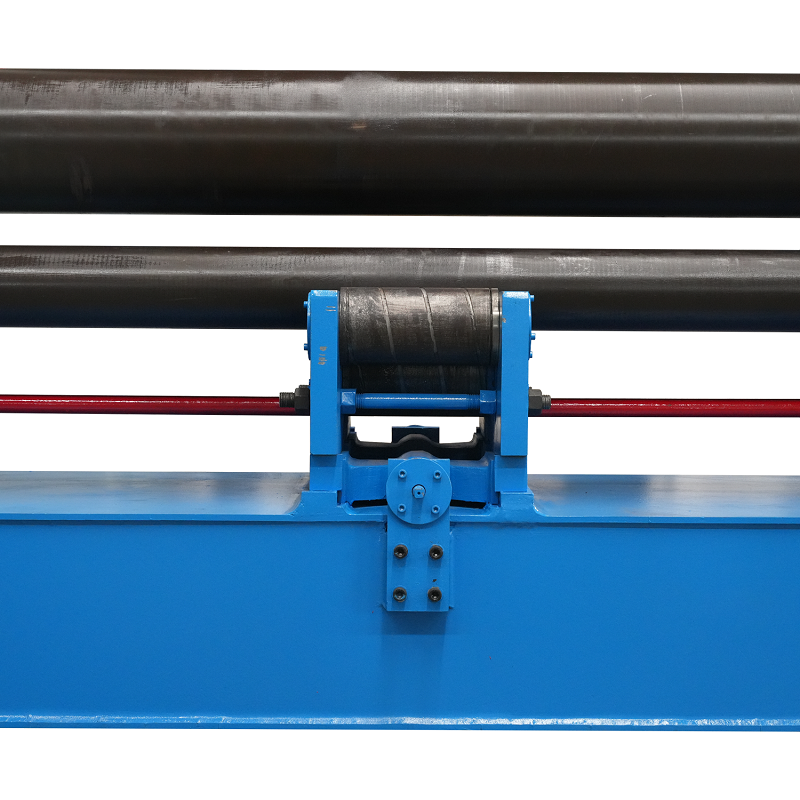

• The top roller is designed as drum shape.Support roller install in the lower of bottom roler to help bending a perfect cylinder from thin to thick plate.

• Special bending craft,high precision pre-bending of the edge,digital control for bending process.

• Rich shape bend such as O,U,R etc.

• Cone bending device for conical bend easily.

• Whole chassis,simple ground foundation,it’s convenient to move the workplace.

• According to the role or requirement of customer,economic digital display type or TNC digital control type is optional;

• CE certificate

Description

3 rolls Hydraulic plate bending machine with double pre-bending.

Useful length from 1000mm to 10000mm.

Thickness from 2 up to 200mm.

Feature:

• The top roller is designed as drum shape.Support roller install in the lower of bottom roler to help bending a perfect cylinder from thin to thick plate.

• Special bending craft,high precision pre-bending of the edge,digital control for bending process.

• Rich shape bend such as O,U,R etc.

• Cone bending device for conical bend easily.

• Whole chassis,simple ground foundation,it’s convenient to move the workplace.

• According to the role or requirement of customer,economic digital display type or TNC digital control type is optional;

• CE certificate

Application Cases

Standard components:

• Solid rolls made by 42CrMo

• PLC control

• Siemens electric parts

• Movable control panel

• Remote control

Optional equipment:

• Machine cover;

• Cone bending device;

• Top support rack for big diameter

• Lateral support rack for big diameter

item |

spec |

|

bearing |

type |

Double row aligning bearing |

manufacture |

Wafangdian,China |

|

Working roller |

material |

42CrMo |

hardened |

Quenching HB240-280 hardened HRC45-52 |

|

manufacture |

Suzhou,China

|

|

Basement and frame |

material |

Q235A |

Process style |

Welding structure,NC boring machine process |

|

Manufacture |

Yeshun,China |

|

gearbox |

type |

ZSY hardened reducer(whole welded machine cover) |

Manufacture |

Weilisi,China |

|

Main electric parts |

Siemens |

|

NC system |

Programmable display |

Touchwin,China |

PLC |

OMRON,Japan |

|

|

Encoder |

Keruite,China |

Main motor |

Lichao,Shanghai/China good brand) |

||

Hydraulic system |

pump |

type |

Gear pump |

Manufacture |

Chuangyuan,China |

||

valve |

Manufacture |

Yuken,Japan |

|

Oil tank |

Cylinder and piston |

Steel 45,quenching HB217-255 |

|

Manufacture |

Yeshun,China |

||

Seal ring |

YX type |

||

Manufacture |

NOK,Japan |

||

Model |

Pressure of top roller(T) |

Max. Bending thickness(mm) |

Pre-bending thickness(mm) |

Max. Bending width(mm) |

Top roller diameter (mm) |

Bottom roller diameter(mm) |

Central distance (mm) |

Main motor(KW) |

||

Drive |

Hydraulic |

Movement

|

||||||||

W11S-4x2500 |

25 |

4 |

3.5 |

2500 |

200 |

125 |

160 |

4 |

2.2 |

1.1 |

W11S-6x2500 |

30 |

6 |

5 |

2500 |

210 |

125 |

160 |

4 |

2.2 |

1.1 |

W11S-8x2000 |

37 |

8 |

6.5 |

2000 |

210 |

135 |

180 |

4 |

2.2 |

1.1 |

W11S-8x2500 |

37 |

8 |

6.5 |

2500 |

235 |

135 |

180 |

5.5 |

2.2 |

1.1 |

W11S-10x2000 |

37 |

10 |

8 |

2000 |

235 |

135 |

180 |

5.5 |

2.2 |

1.1 |

W11S-10x2500 |

55 |

10 |

8 |

2500 |

250 |

145 |

200 |

7.5 |

4 |

1.1 |

W11S-12x2000 |

65 |

12 |

10 |

2000 |

250 |

145 |

200 |

7.5 |

4 |

1.1 |

W11S-12x2500 |

75 |

12 |

10 |

2500 |

265 |

145 |

200 |

7.5 |

4 |

1.5 |

W11S-12x3000 |

75 |

12 |

10 |

3000 |

290 |

150 |

245 |

11 |

4 |

1.5 |

W11S-16x2000 |

75 |

16 |

13 |

2000 |

265 |

150 |

245 |

7.5 |

4 |

1.5 |

W11S-16x2500 |

100 |

16 |

13 |

2500 |

300 |

165 |

270 |

15 |

5.5 |

1.5 |

W11S-16x3000 |

130 |

16 |

13 |

3000 |

330 |

180 |

300 |

15 |

5.5 |

2.2 |

W11S-20x2000 |

100 |

20 |

16 |

2000 |

300 |

165 |

270 |

15 |

5.5 |

1.5 |

W11S-20x2500 |

130 |

20 |

16 |

2500 |

330 |

180 |

300 |

15 |

5.5 |

2.2 |

W11S-20x3000 |

160 |

20 |

16 |

3000 |

380 |

200 |

330 |

18.5 |

7.5 |

2.2 |

W11S-20x4000 |

230 |

20 |

16 |

4000 |

440 |

235 |

380 |

30 |

11 |

4 |

W11S-25x2500 |

190 |

25 |

20 |

2500 |

380 |

220 |

360 |

22 |

7.5 |

4 |

W11S-25x3000 |

230 |

25 |

20 |

3000 |

410 |

235 |

380 |

30 |

11 |

4 |

W11S-25x4000 |

270 |

25 |

20 |

4000 |

490 |

250 |

400 |

30 |

11 |

4 |

W11S-30x2500 |

230 |

30 |

25 |

2500 |

410 |

235 |

380 |

30 |

11 |

4 |

W11S-30x3000 |

270 |

30 |

25 |

3000 |

450 |

250 |

400 |

30 |

11 |

4 |

W11S-30x4000 |

380 |

30 |

25 |

4000 |

550 |

275 |

460 |

45 |

22 |

5.5 |

W11S-35x2500 |

320 |

35 |

28 |

2500 |

450 |

250 |

400 |

30 |

11 |

4 |

W11S-35x3000 |

380 |

35 |

28 |

3000 |

510 |

275 |

460 |

45 |

22 |

5.5 |

W11S-40x2500 |

380 |

40 |

32 |

2500 |

500 |

275 |

460 |

45 |

22 |

5.5 |

W11S-40x3000 |

430 |

40 |

32 |

3000 |

540 |

290 |

500 |

55 |

22 |

7.5 |

W11S-40x4000 |

540 |

40 |

32 |

4000 |

630 |

340 |

610 |

55 |

22 |

11 |

W11S-45x3000 |

540 |

45 |

36 |

3000 |

590 |

340 |

610 |

55 |

22 |

11 |

W11S-50x2500 |

430 |

50 |

40 |

2500 |

580 |

290 |

500 |

55 |

22 |

7.5 |

Company Profile

Nantong Yeshun Machinery Manufacture Co., Ltd. was established in 2003, located in the advanced industrial city--Haian. It's a professional manufacture of metal plate processing equipment such as plate rolling machine and profile bending machine, press brake, guillotine shearing machine and laser cutting machine, etc.

In recent years, we have absorbed foreign advanced technology, research and developed series CNC products with independent intellectual property rights and international advanced level. We have more than a dozen varieties type of plate rolling machine and profile bending machine(W12 CNC four rolls plate bending machine, W11 three rolls symmetrical plate bending machine, W11F asymmetrical plate bending machine, W11S heavy duty upper universal plate bending machine, W11H arc adjust plate bending machine, W24S full hydraulic profile bending machine, WYQ24 semi-hydraulic profile bending machine,etc.), WC67Y(K) press brake, QC11Y(K) guillotine shear, laser cutting machine, hydraulic press, ironworker and other models.

Besides, our factory has a complete set of well-known processing equipment with advanced technology and high precision, and strictly implements the ISO9001 quality system standard, which has laid a solid foundation for the production of high-quality products. All products produced by the factory have independent and experienced before-sales and after-sales service to better satisfy the customer’s needs throughout the world.