Description

Small detachable desktop plasma/flame cutting machine

1.Introduction

CNC plasma/flame cutting system can cut arbitrary planar shape partsthat can be composed ofa straight line and arc,the dynamic and static graphicsisintuitiveand alsoeasy to learn, can be directlyprogrammedon the machine, also can draw on the computer or use existing CAD file by attached softwaretodirectly converttoG code program files, realize automatic cutting throughcopyingthe U disk to the operating system.

This kind of plasma cutting machine also adoptsgantry bilateral drive structure. The system structureiscompactwithhigh-levelautomation, simple operation, convenient maintenanceandhigh reliability. Itcan easily cutdifferent platefromthinsheet metal to large thickness steel plate. Products are widely used in all kinds of manufacturing in the field of sheet metal cutting blanking process,cutting such ascarbon steel, stainless steel, alloy steel, aluminum and other non-ferrous metal sheet.

Product features

X axis and Y axisof the machineare equipped with high-precision planetary reducer. Product highlights: compact structure, small return clearance, greater driving torque, high precision, no mechanical resonance, more stable operation, prolong the life of mechanical and electrical.

二、Basic configuration

No |

Main parts |

Unit |

Qty |

Description |

1 |

Machine Model |

set |

1 |

YS-2090 |

2 |

Overall dimension |

mm |

1 |

2500mm×4300mm |

3 |

Effective cutting stroke |

mm |

1 |

1500mm×3000mm |

4 |

Longitudinal guide rails |

piece |

2 |

|

5 |

CNC system |

set |

1 |

FL CNC system |

6 |

Drive mode |

set |

1 |

Rack drive (precision gear and rack) |

7 |

Motor mode |

set |

3 |

Leadshine |

8 |

Precision planetary gearbox |

set |

3 |

PL57/Taiwan |

9 |

Cutting torch lifting device |

set |

1 |

Gaochuang |

10 |

Plasma power |

set |

1 |

optional |

11 |

Automatic arc voltage type adjustment device |

set |

1 |

HYD |

12 |

Pneumatic pipecontrol |

piece |

1 |

SAM ACT, South Korea |

13 |

Wire/cable drive |

set |

1 |

Heavy engineering towing chain (55×100mm inside) |

14 |

Photoelectric switch and proximity sensor |

set |

1 |

AIRTAC / Taiwan |

15 |

Cutting mode |

1 |

Flame |

|

16 |

Cutting torch control mode |

piece |

1 |

Programme control |

17 |

Cutting torch |

piece |

1 |

Flame cutting torch |

18 |

Limit switch |

group |

6 |

2 groups for each axis of X.Y.Z |

19 |

Standard software |

set |

1 |

Fastcam |

三、TechnicalIndicators

No |

Item |

Indicators |

||

1 |

Cutting torch lifting distance |

100m |

||

2 |

Machine speed |

0-6000mm/min |

||

3 |

Cutting thickness |

Plasma |

1-10mm |

|

4 |

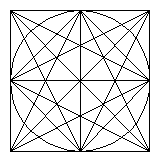

Overall precision (Refer to the comprehensive graph on the right)Side length(four sides)1000*1000 Line speed:500-800mm/min |

|

||

5 |

Intersection point offset |

±1.0mm |

|

|

6 |

Straightness |

±0.5mm |

||

7 |

Roundness |

±1.0mm |

||

8 |

Diagonal error |

±1.0mm |

||

9 |

Repetitive positioning accuracy |

±0.5mm |

||

10 |

Machine marking line accuracy |

≦0.5mm |

||

11 |

Cutting surface quality (roughness) (choose δ=25 plate) |

RZ(um)=70+1.2a, visual inspection: roughness 12.5 |

||

Company Profile

Nantong Yeshun Machinery Manufacture Co., Ltd. was established in 2003, located in the advanced industrial city--Haian. It's a professional manufacture of metal plate processing equipment such as plate rolling machine and profile bending machine, press brake, guillotine shearing machine and laser cutting machine, etc.

In recent years, we have absorbed foreign advanced technology, research and developed series CNC products with independent intellectual property rights and international advanced level. We have more than a dozen varieties type of plate rolling machine and profile bending machine(W12 CNC four rolls plate bending machine, W11 three rolls symmetrical plate bending machine, W11F asymmetrical plate bending machine, W11S heavy duty upper universal plate bending machine, W11H arc adjust plate bending machine, W24S full hydraulic profile bending machine, WYQ24 semi-hydraulic profile bending machine,etc.), WC67Y(K) press brake, QC11Y(K) guillotine shear, laser cutting machine, hydraulic press, ironworker and other models.

Besides, our factory has a complete set of well-known processing equipment with advanced technology and high precision, and strictly implements the ISO9001 quality system standard, which has laid a solid foundation for the production of high-quality products. All products produced by the factory have independent and experienced before-sales and after-sales service to better satisfy the customer’s needs throughout the world.