Laser cutting machine

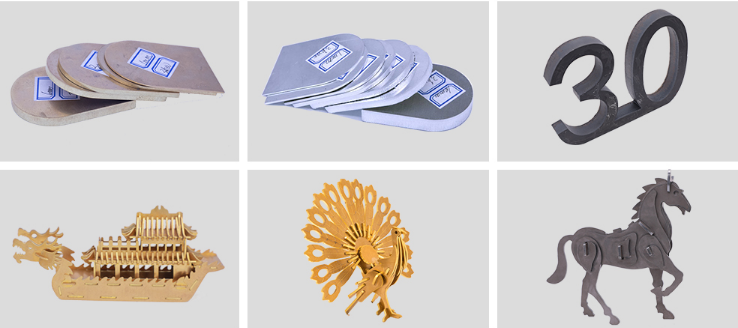

Suitable for cutting various metal sheets, pipes (additional pipe cutting device required), primarily used for rapid cutting of materials such as stainless steel, carbon steel, galvanized sheet, electrolytic plate, brass, aluminum sheet, manganese steel, various alloy sheets, and rare metals

Imported original packaged fiber laser,excellent beam quality,stable performance.

High electro-optical conversion efficiency of the fiber laser,achieving a conversion efficiency of 30% significantly reducing power consumption during operation and extremely low operating costs.

Fast cutting speed,extremely low operating cost,providing a quick return on investment.

Description

Introduction:

Fiber laser cutting machine is used in sheet metal processing, advertising sign production, cabinet electrical cabinets, mechanical parts, kitchenware, sanitary ware, auto parts, machinery manufacturing, metal crafts, saw blades, electrical parts, glasses industry, spring sheets, circuit boards, electrical Kettles, medical microelectronics, hardware, doors and windows and other industries.

The advantages of fiber laser cutting machine:

1.Extremely high cutting speed: twice as much as the CO2 laser cutting machine with the same power, and at the same time meeting the cutting requirements of plate and pipe;

2.Extremely high stability: The service life of key components can reach 100,000 hours,which greatly saves costs;

3.Extremely low use cost: The power consumption of the whole machine is only 20%-30% of the similar CO2 laser cutting machine;

4.Extremely low maintenance costs: Fiber optic transmission,no need for reflective lenses, saving a lot of maintenance costs;

5.The product is easy to operate and maintain, with optical fiber transmission,no need to adjust the circuit.

Main configuration:

1.Machine body:

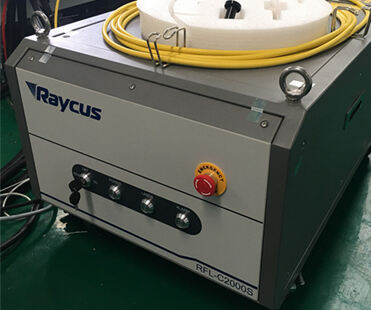

2.Raycus brand 1500w fiber generator

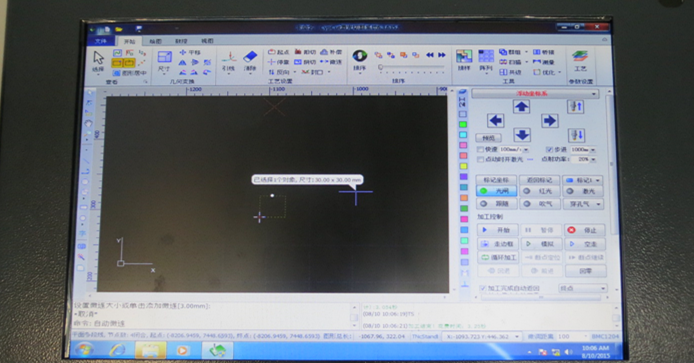

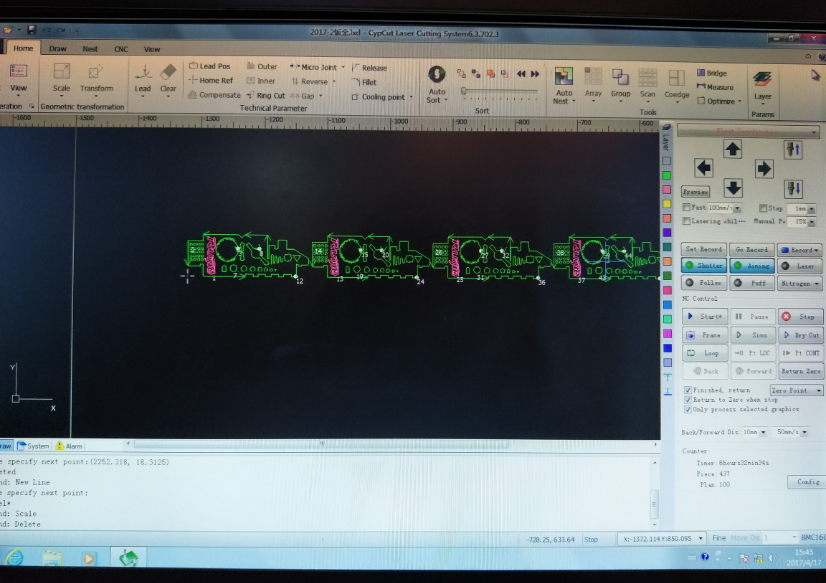

3.Cypcut control system:

4.Industrial water chiller : S&A

5.Auto following laser cutting head: raytools auto focus.

Automatically adjust the focal distance according to the bump degree of plate, Raytools.

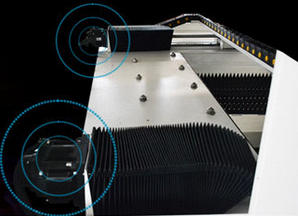

6.Automatic follow up system

7.Japanese Fuji dual-servo driver ( Dual drivers for Y axis, faster and more powerful)

8.Wireless controller

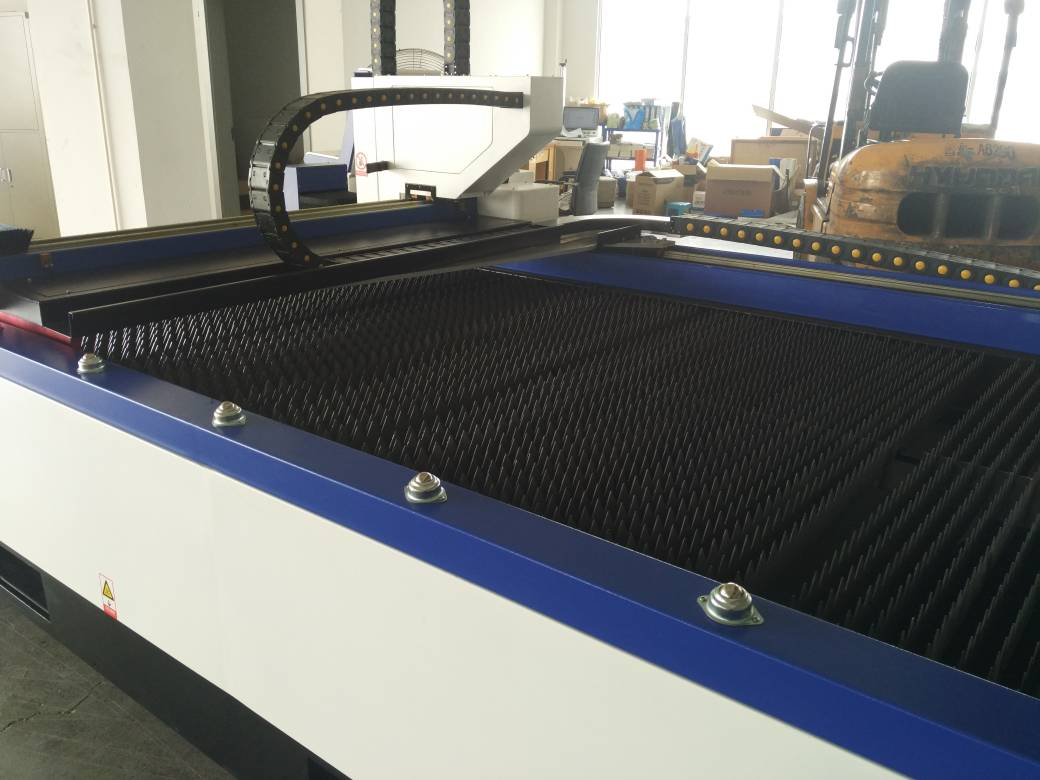

9.All around design with ball bearing, easy for edge feeding.

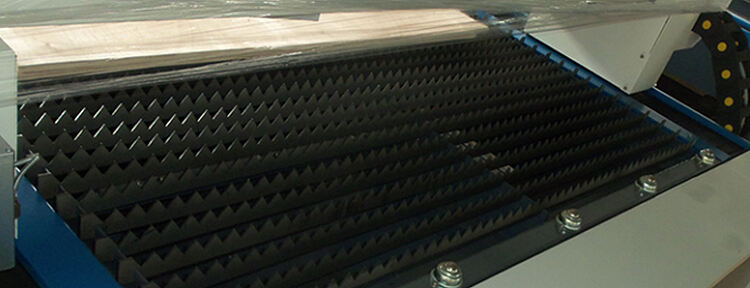

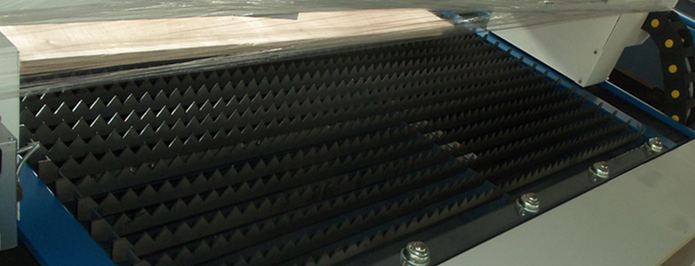

10.Sawtooth blade table, suitable for sheet metal cutting.

Spare parts:

Item |

Amount |

Specification |

Remarks |

||

Laser with accessories |

A |

Fiber laser generator |

1 |

Raycus |

For cutting |

B |

Laser cutting head |

1 |

bm109 |

Auto focusing |

|

C |

Water chiller |

1 |

Hanli |

S&A/Tongfei Optional |

|

D |

Cutting system |

1 |

FSCUT 2000c |

Cypcut |

|

Structural accessories |

E |

Working bed |

1 |

|

|

F |

X axis rack |

1 |

|

YYC |

|

G |

Y axis rack |

2 |

|

YYC |

|

H |

Guide rail |

3 |

|

HIWIN |

|

I |

X、Y servo and driver |

3 |

|

FUJI,Japan |

|

J |

Reducer |

3 |

|

France motor reducer |

|

K |

Control box |

1 |

|

FQ China |

|

L |

Machine accessories |

1 |

|

FQ China |

|

Supporting products |

M |

Electric voltage regulator |

1 |

|

Shanghai Xishun |

N |

Dust removal fan |

1 |

|

||

Application Cases

Company Profile

Nantong Yeshun Machinery Manufacture Co., Ltd. was established in 2003, located in the advanced industrial city--Haian. It's a professional manufacture of metal plate processing equipment such as plate rolling machine and profile bending machine, press brake, guillotine shearing machine and laser cutting machine, etc.

In recent years, we have absorbed foreign advanced technology, research and developed series CNC products with independent intellectual property rights and international advanced level. We have more than a dozen varieties type of plate rolling machine and profile bending machine(W12 CNC four rolls plate bending machine, W11 three rolls symmetrical plate bending machine, W11F asymmetrical plate bending machine, W11S heavy duty upper universal plate bending machine, W11H arc adjust plate bending machine, W24S full hydraulic profile bending machine, WYQ24 semi-hydraulic profile bending machine,etc.), WC67Y(K) press brake, QC11Y(K) guillotine shear, laser cutting machine, hydraulic press, ironworker and other models.

Besides, our factory has a complete set of well-known processing equipment with advanced technology and high precision, and strictly implements the ISO9001 quality system standard, which has laid a solid foundation for the production of high-quality products. All products produced by the factory have independent and experienced before-sales and after-sales service to better satisfy the customer’s needs throughout the world.