Description

1. Main Features:

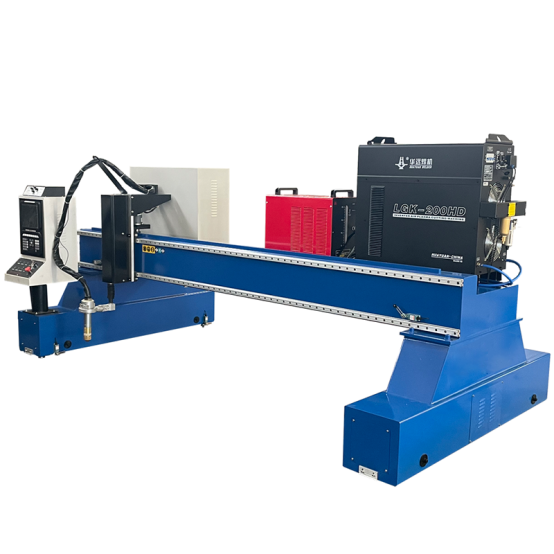

- Adopting Sweden ESAB, Japan KOIKE beam, square tube structure through stress-relief and surface oxidation treatment, with high rigidity, high strength, corrosion resistance and guaranteed operation accuracy.

- Cutting torch lifter use towing chain type cable trailer to ensure that the air-pipes, wires be in good protection;

- Cross-beam lifter use one main and multi servo movement method in horizontal direction, up to 6 lifers can be installed on, that is,6 cutting torches, each lifter equipped with a cutting torch and a lifting mechanism;

- In longitudinal direction, using bilateral drive method;

- Longitudinal configuration is equipped with high-precision rack, dedicated heavy-duty railroad rail ( NO.40 rail ), running reliably and accurately, and working surface use finishing grinding technology to ensure the smooth operation and accuracy of the machine.

2. Standard Configuration:

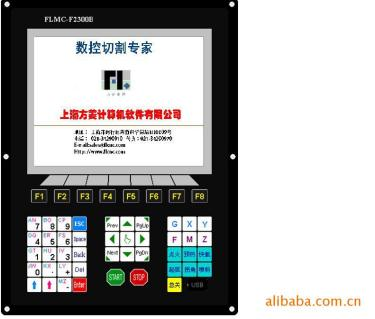

- Shanghai Fangling F2300 CNC system

- X,Y-axes use linear guide rail, Z-axis use ball screw

- HIWIN ball screw and polished rod with accuracy of 0.05mm

- Fixed type large-scale operation system

- Adopting FASTCAM/SMARTCUT CNC cutting software

- Adopting Japan Panasonic P80 cutting head

- X-axis driven by double motors, Y-axis driven by single motor

- France Schneider electrics

- Safety standard(2006/42/EC)

3. Arc-Voltage Regulator:

- HP1201 portable arc-voltage regulator, designed for portable CNC cutting machine, light gantry CNC cutting machine.

- Can be embedded into the cabinet panel, good integration, simple wiring

- New brand design, use SMT ( Surface Mount Technology ) and the latest chip design

- Comprehensively enhance the reliability and anti-interference ability, adding a variety of protection circuit

- Liquid crystal display, real-time display status and parameters, simple and intuitive

- Built-in “isolated voltage plate”, can match with the 1: 1 or 50: 1 arc-voltage input

- Intelligent arc voltage, control accuracy, manual speed, automatic sensitivity and other adjustable parameters

- All-in-one console that can be directly embedded into cutting machine, full-featured, compact body,

- High precision voltage collection, PWM control DC motor, smooth operation, high sensitivity

4. Flame Cutting Gun:

- The whole machine is manufactured by high-quality forged steel

- Adopting equal pressure structure

- The outside diameter of the casing tube is 30mm and 32mm

- Five different lengths of casing tube: 180mm, 250mm, 370mm, 450mm

- The rack can be installed in four different positions ( apart 90 °each position )

- Applicable to the equal-pressure cutting tip with 30-degree conical surface

5. Australia FASTCAM (Standard Edition) Software:

- Australian FASTCAM ( Standard Edition ) software is the standard software, as for automatic nesting and common side, you need select SMARTNEST ( Expert Edition ) or FASTCAM ( Expert Edition ), which can convert CAD graphics or computer graphics into G code for cutting parts, G code files will be restored into USB and input into the cutting machine, then the controller automatically converts the G code into cutting program. This kind product is equipped with USB interface convenient for the program transmission. Set the slit compensation value in nesting software. Program software ZZ-TL ( optional FASTCAM ) is AutoCAD-based automatic programming and nesting system, Designed for all kinds of CNC cutting machine, it can help users drawing, programming and nesting to the utmost, it is not only easy to operate, but also bring obvious economic benefits for users.

- Drawing method: Taking advantage of AutoCAD powerful drawing function for parts drawing, nesting, and through DXF, DWG file data processing; automatically generate the necessary cutting codes.

- Cutting process: the cut-in point can be from the corner or edge; cutting way you can choose circular or linear cut-in; slit compensation function can calculate the actual cutting trajectory; cutting path and direction can be set at will.

- Nesting means: based on AutoCAD free operation on parts drawing, such as translation, rotation, replication, mirroring, scaling, array etc. the nesting can be enlarged for fine treatment through the window operation technology.

-

Screen simulation: the actual cutting processing trajectory can be simulated on the screen, simulating the cutting process, and can zoom, move arbitrarily.

Intelligent nesting software supports R12, R13, R14, A4, 2002, 2004, 2005, 2007 and other edition AutoCAD.

NO. |

Name |

Model |

Quantity(set) |

Picture |

1 |

CNC |

HONEYBEECNC |

1 set |

|

2 |

Vertical servo system |

Panasonic 400W |

2 sets |

|

3 |

Horizontal servo system |

Panasonic 400W |

1 set |

|

4 |

Programme software |

Australia FASTCAM |

1 set |

|

5 |

Plasma Power |

USA PowerMAX125A

USA PowerMAX200A

LGK-200HA

|

1 set |

|

6 |

Hose |

Korea YASUNG |

1 set |

|

7 |

Solenoid valve |

Taiwan |

1 set |

|

10 |

Flame cutting gun |

USA,JIERUI |

1 set |

|

11 |

Power |

TAIWAN |

1 set |

|

12 |

Towline |

Made in China |

1 set |

|

13 |

Gears, rack |

m=2.0 |

1 set |

Made in China |

Company Profile

Nantong Yeshun Machinery Manufacture Co., Ltd. was established in 2003, located in the advanced industrial city--Haian. It's a professional manufacture of metal plate processing equipment such as plate rolling machine and profile bending machine, press brake, guillotine shearing machine and laser cutting machine, etc.

In recent years, we have absorbed foreign advanced technology, research and developed series CNC products with independent intellectual property rights and international advanced level. We have more than a dozen varieties type of plate rolling machine and profile bending machine(W12 CNC four rolls plate bending machine, W11 three rolls symmetrical plate bending machine, W11F asymmetrical plate bending machine, W11S heavy duty upper universal plate bending machine, W11H arc adjust plate bending machine, W24S full hydraulic profile bending machine, WYQ24 semi-hydraulic profile bending machine,etc.), WC67Y(K) press brake, QC11Y(K) guillotine shear, laser cutting machine, hydraulic press, ironworker and other models.

Besides, our factory has a complete set of well-known processing equipment with advanced technology and high precision, and strictly implements the ISO9001 quality system standard, which has laid a solid foundation for the production of high-quality products. All products produced by the factory have independent and experienced before-sales and after-sales service to better satisfy the customer’s needs throughout the world.