الدرفلة الساخنة مقابل الباردة: العمليات، والأداء، والتطبيقات

كيف تُشكل الدرفلة الساخنة الفولاذ عند درجات حرارة عالية

عندما تُدرَس الصلب عند درجات حرارة أعلى من ما يُعرف بنقطة إعادة التبلور، وعادة ما تكون بين 900 إلى 1200 درجة مئوية، يصبح المعدن أسهل في التشكيل دون الحاجة إلى قوة كبيرة، كما يزداد معدنه مطاوعة أيضًا. لقد أصبحت طريقة الدرفلة الساخنة شائعة جدًا عبر الصناعات لإنتاج أشياء مثل العوارض على شكل حرف I للمباني، وسكة القطارات، والألواح الفولاذية الثقيلة التي نراها في كل مكان. بعد المرور بهذه العملية من التسخين والتشكيل، يميل الصلب إلى التبريد السريع، مما يُكوّن تركيبة بلورية أفضل داخل المادة. وفقًا لبعض البيانات الصناعية من تقرير معالجة المعادن للعام الماضي، فإن هذا يجعل المنتج النهائي يؤدي أداءً أفضل في نحو أربع من كل خمس حالات عند النظر إلى جميع التطبيقات الصناعية. ومع ذلك، هناك سلبيات تستحق الذكر. فالمادة تميل إلى تكوين طبقة أكسيد على السطح تُعرف عادةً باسم القشرة أثناء التبريد، كما يمكن أن تختلف الأبعاد بنسبة تقريبًا 1.5 بالمئة إما زيادة أو نقصانًا. وعمومًا، تجعل هذه الخصائص الصلب المدرفل على الساخن غير مناسب للأجزاء التي تتطلب مقاييس دقيقة جدًا أو تشطيبات سطحية ناعمة للغاية.

الدرفلة الباردة من أجل الدقة والقوة ونهاية السطح

عند درفلة الفولاذ على البارد عند درجات حرارة الغرفة، فإننا نضغطه بين 15 إلى 50 بالمئة تقريبًا، مما يجعله أكثر صلابة من خلال ما يُعرف بالتصلب بالانفعال. والنتيجة؟ فولاذ يمكنه تحمل توتر أكبر بنسبة 25% تقريبًا مقارنةً بالفولاذ المسحوب على الساخن. بالإضافة إلى ذلك، تصبح الأسطح ناعمة جدًا أيضًا، وغالبًا ما تكون خشونة السطح أقل من 0.8 ميكرون. ويُعد التحكم في السمك ميزة كبيرة أخرى. نحن نتحدث عن تحملات تبلغ حوالي زائد أو ناقص 0.05 ملم. هذه الدقة مهمة جدًا في ألواح هيكل السيارة، وأغلفة الثلاجات، والصناديق الصغيرة التي تحتوي على الإلكترونيات. عندما يكون المظهر مهمًا بقدر أهمية القياسات، فإن الفولاذ المسحوب على البارد يعمل بشكل أفضل بكثير في جميع الجوانب.

مقارنة الفولاذ المسحوب على الساخن مع الفولاذ المسحوب على البارد: الاختلافات الرئيسية وحالات الاستخدام

| الممتلكات | الفولاذ المدلفن ساخناً | الصلب المدرفل باردًا |

|---|---|---|

| درجة حرارة المعالجة | 900–1200°م | درجة حرارة الغرفة |

| اللمسة النهائية للسطح | مؤكسد، خشن (Ra 3–6µم) | ناعم (Ra 0.4–1.6µم) |

| القوة | 400–550 ميجا باسكال حد الخضوع | 550–800 ميجا باسكال حد الخضوع |

| التطبيقات النموذجية | الجسور، بناء السفن | أجسام السيارات، أنظمة التكييف والتدفئة |

تُظهر تقارير الصناعة أن الصلب المدلفن على البارد يستحوذ حاليًا على حوالي 62٪ من سوق التصنيع الدقيق، نظرًا لأنه يوفر نتائج متسقة وتشطيبات سطحية أفضل. لا يزال الصلب المدلفن على الساخن قويًا في مشاريع البناء الكبيرة، حيث يهتم المقاولون غالبًا بتقليل التكاليف أكثر من تحقيق التحملات الضيقة جدًا. تتطلب الآلات المستخدمة في كل عملية إعدادات مختلفة للاستفادة القصوى من دورات الإنتاج وإدارة استهلاك الطاقة بشكل مناسب. ويجب على الشركات المصنعة موازنة هذه العوامل عند الاختيار بين الخيارين بناءً على متطلبات مشروعها الخاص.

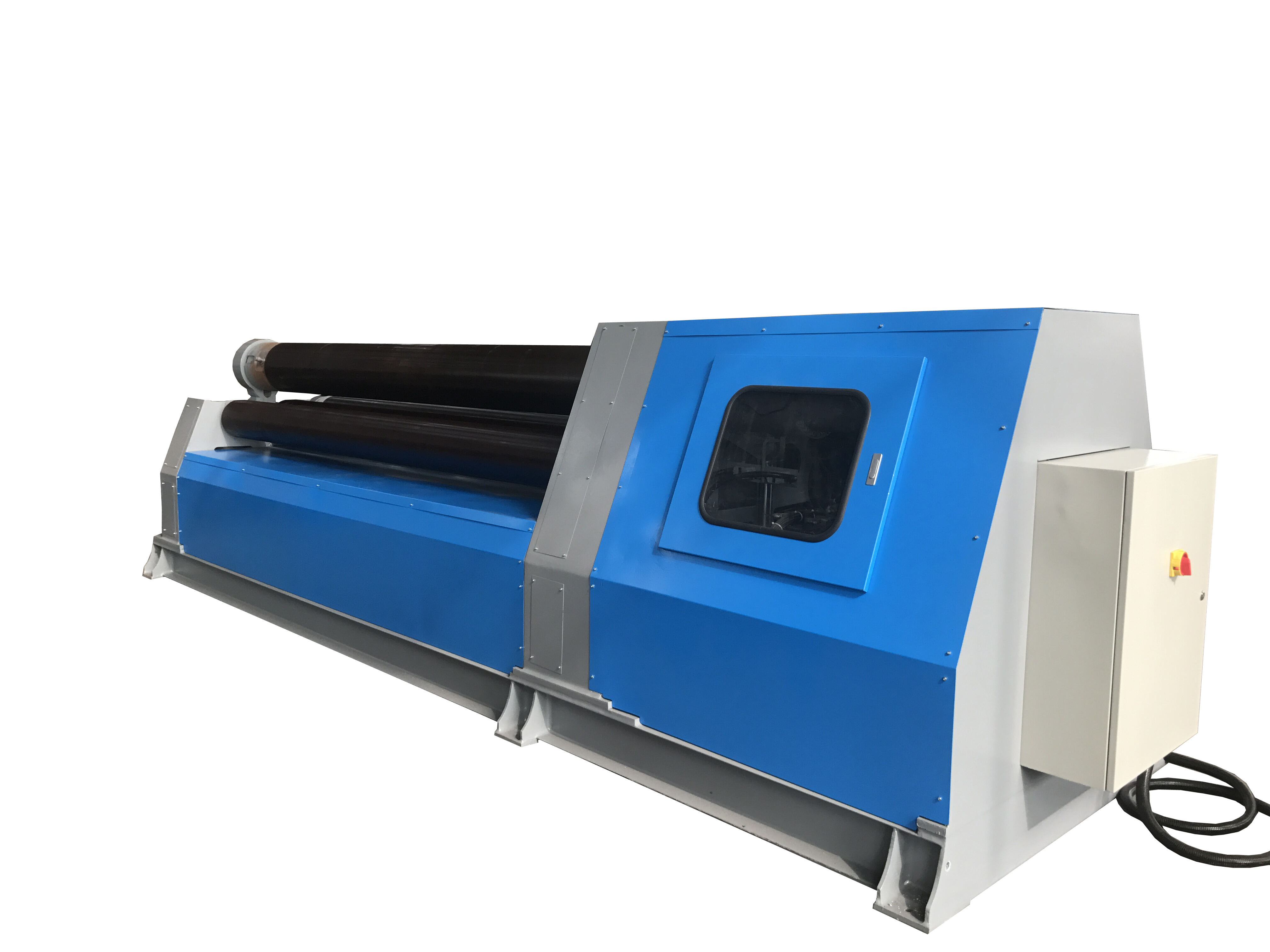

أنواع تطور آلات دحرجة الصلب: من اليدوية إلى CNC

يُجسّد تطور آلات دحرجة الصلب — من الأنظمة اليدوية إلى الأنظمة الخاضعة للتحكم الحاسوبي — التحولات الأوسع نحو الأتمتة والدقة والكفاءة التشغيلية في التصنيع الحديث.

الآلات الدوارة اليدوية وشبه الأوتوماتيكية: سير العمل التقليدي

في الماضي، كانت أنظمة الدرفلة تعتمد كليًا على العمل اليدوي، حيث يقوم المشغلون بإجراء التعديلات والتحقق يدويًا من السُمك. وعندما ظهرت النسخ شبه التلقائية، أُضيف دعم ميكانيكي لمهام مثل تغذية الملفات، مما قلّص وقت الإنتاج بنسبة تقارب 20 في المئة مقارنةً بالعمل اليدوي البحت وفقًا لبحث بونيمان لعام 2023. ومع ذلك، حتى مع هذه الترقيات، لم تستطع معظم الورش إنتاج سوى نحو 40 إلى 60 صفيحة في الساعة، لأن هناك حاجة دائمة لمراقبة العملية عن كثب طوال التشغيل.

مطاحن الدرفلة الأوتوماتيكية والتكامل مع خطوط الإنتاج الذكية

تستخدم المطاحن الحديثة الآلية وحدات تحكم منطقية قابلة للبرمجة (PLCs) لمزامنة سرعات الأسطوانات مع أنظمة النقل، ما يتيح تشغيلًا مستمرًا على مدار الساعة. وعند دمجها مع منصات تصنيع مدعومة بتقنية إنترنت الأشياء (IoT)، تستفيد هذه الأنظمة من بيانات الاستشعار الفورية لتعديل المعايير ديناميكيًا، مما يقلل هدر المواد بنسبة تتراوح بين 15 و30 في المئة في معالجة الصفائح المعدنية وفقًا للمعايير الصادرة في عام 2024.

آلات الدحرجة باستخدام التحكم العددي بالحاسوب: تعزيز الكفاءة بنسبة تصل إلى 40%

لقد غيرت تكنولوجيا التحكم العددي بالحاسوب (CNC) طريقة عمل عمليات دحرجة المعادن بشكل جذري، بفضل المحركات المؤازرة التي تحقق دقة تبلغ حوالي زائد أو ناقص 0.05 مليمتر في معظم الأحيان. إن هذه الآلات الحديثة تدمج فعليًا خوارزميات التعلّم الآلي لتحديد أفضل مسارات الأدوات، ما يعني أنها تعمل بسرعة تزيد بنسبة 40 بالمئة تقريبًا مقارنةً بالعمليات اليدوية التقليدية، دون المساس بثبات المنتج من دفعة إلى أخرى. ما يجعل هذه الأنظمة قوية جدًا هو قدرتها على العمل بتناغم مع حزم برامج CAD وCAM. كما انخفضت أوقات الإعداد بشكل كبير أيضًا؛ إذ أصبح من الممكن إعداد الأشكال المعقدة التي كانت تستغرق سابقًا ثماني ساعات كاملة للتهيئة خلال أقل من 45 دقيقة اليوم.

المكونات الرئيسية وصيانة آلات دحرجة الفولاذ

تعتمد آلات دحرجة الصلب على مكونات عالية الدقة وبرامج صيانة منضبطة لضمان الموثوقية والطول الزمني للعمل والإنتاج المستمر.

الدرافيل وتكوينات الدرفلة في مصانع الدحرجة الحديثة

تشكل الأدوات الركيزة العمود الفقري لآلات التدحرج، حيث تمارس الضغط الكافي فقط لتخفيف المواد أو إعادة تشكيل مقاطعها العرضية. هناك العديد من الإعدادات القياسية في الممارسة الصناعية هذه الأيام - فكر في ترتيبات مرتفعة 2 للعمليات الأساسية، وأنظمة مرتفعة 4 عندما تكون هناك حاجة إلى مزيد من الدقة، وتلك المطاحن المجمعة المعقدة التي تتعامل مع وظائف صعبة حقا. تساعد الخنادق المقطعة في بعض الأدوات على تشكيل أشياء مثل قضبان التأهيل والعصي المعدنية، في حين أن تلك اللطيفة تخرج أوراقاً مسطحة لطيفة وألواح سميكة دون أي تشوه. التحول من الصلب العادي إلى مواد سبائك أصعب يُحدث فرقًا حقيقيًا أيضًا. تظهر اختبارات الصناعة أن هذه الأدوات المُحسنة تستمر لمدة أطول بنسبة 40 في المائة قبل الحاجة إلى استبدالها، مما يعني حوادث أقل من وقت التوقف وتكاليف صيانة أقل بشكل عام.

محامل، وسلسلة، ونظم القيادة: ضمان استقرار التشغيل

- الدب|array : تحمل الوسادات المخروطية الأحمال المحورية والشعاعية في العمليات عالية السرعة، وتقلل من الاحتكاك بين الأسطوانات الدوارة والإطارات الثابتة.

- هيكل : تمتص هياكل الفولاذ المعززة القوى الديناميكية التي تتجاوز 12 طنًا أثناء الدرفلة الساخنة، مما يضمن سلامة الهيكل.

- أنظمة الدفع : تحافظ محركات التيار المتناوب المتزامنة على التحكم الدقيق بالعزم عبر فجوات الدرفلة الضيقة جدًا والتي قد تصل إلى 0.5 مم، وهي أمر بالغ الأهمية للتشوه الموحّد.

تحاليل المحاذاة المنتظمة تمنع 78% من الإيقافات غير المخطط لها الناتجة عن سوء المحاذاة الميكانيكية (مجلة الهندسة الصناعية، 2023).

التحديات الشائعة في الصيانة والممارسات المثلى

تشمل التحديات الرئيسية في صيانة آلات الدرفلة ما يلي:

| التحدي | حل | التردد |

|---|---|---|

| تآكل سطح الأسطوانة | إعادة الطحن أو الطلاء بالكروم | كل 500 ساعة تشغيل |

| ارتفاع درجة حرارة المحامل | فحص لزوجة مواد التشحيم | أسبوعياً |

| تسريبات الهيدروليك | استبدال الختم واختبارات الضغط | ربع سنوي |

إن تطبيق استراتيجيات الصيانة التنبؤية—مثل تحليل الاهتزاز والتصوير الحراري—يقلل من وقت التوقف بنسبة 30%. كما أن تسجيل الاختلافات التشغيلية اليومية يدعم اكتشاف الأعطال مبكرًا، وقد أثبتت الدراسات أنه يُطيل عمر المعدات من 7 إلى 12 عامًا في البيئات شديدة الاستخدام.

الاتجاهات المستقبلية: الثورة الصناعية الرابعة، والأتمتة، ودرفلة الصلب المستدامة

المستشعرات الذكية والصيانة التنبؤية تقلل من وقت التوقف بنسبة 30%

في الوقت الحاضر، تحتوي معظم مصانع الدرفلة الحديثة على أجهزة استشعار إنترنت الأشياء (IoT) تتعقب كل شيء بدءًا من التغيرات في درجة الحرارة واهتزازات المعدات إلى علامات البلى أثناء حدوثها. تُظهر أحدث إحصائيات اتجاهات صناعة الصلب لعام 2024 أمرًا مثيرًا للاهتمام حول هذه الأنظمة الذكية للرصد. إذ تشير المصانع التي تستخدم الصيانة التنبؤية القائمة على بيانات المستشعرات إلى انخفاض بنسبة 30 بالمئة تقريبًا في الأعطال المفاجئة مقارنة بتلك التي تنتظر حدوث الأعطال. وما الذي يجعل هذا أفضل؟ تقوم خوارزميات متقدمة للتعلم الآلي بتحليل سجلات الأداء السابقة ويمكنها بالفعل التنبؤ بموعد تعطل القطع قبل حدوثه بأسبوع إلى أسبوعين تقريبًا. وهذا يمنح فرق الصيانة تحذيرًا مبكرًا كافيًا لإصلاح المشكلات قبل أن تتعرض الإنتاجية للانقطاع.

الذكاء الاصطناعي والنسخ الرقمية في تحسين ماكينات درفلة الصلب

تُنشئ تقنية النموذج الرقمي نسخًا افتراضية من مطاحن الدرفلة في العالم الواقعي، مما يسمح للمصنّعين باختبار تغييرات العمليات مع الاستمرار في تشغيل الإنتاج بشكل طبيعي. وعند دمج هذه الأنظمة مع الذكاء الاصطناعي، فإنها تقلل وقت الإعداد بنسبة تقارب 25٪ وتجعل التحملات في السماكة أكثر اتساقًا بكثير – حوالي 12٪ أفضل فعليًا. يقوم النظام بتعديل سرعة البكرات ويُطبّق كمية الضغط المناسبة حسب نوع الصلب الذي يمر عبر الخط وحالته الحالية. يعني هذا التعديل الذكي أن المصانع تتخلص من كميات أقل بكثير من المواد كخردة مقارنة بالطرق التقليدية.

الابتكارات المستدامة: تقليل استهلاك الطاقة في مطاحن الدرفلة

تعمل أنظمة الدفع الاسترجاعية من خلال استغلال الطاقة الناتجة عند تباطؤ تلك الأسطوانات الثقيلة أثناء التشغيل، ثم إعادة تغذية هذه الطاقة المستمدة لتشغيل معدات أخرى في المصنع. شهدنا حتى الآن انخفاضًا في استهلاك الطاقة بنسبة تقارب 15 بالمئة في بعض الإعدادات التجريبية. وبالنظر إلى التحسينات الخضراء الأخرى، بدأ المصنعون بتجربة أفران التلدين التي تعمل بالهيدروجين بدلًا من الأفران التقليدية، في حين انتقل آخرون إلى استخدام مواد تشحيم مستخلصة من مصادر نباتية في عمليات الدرفلة الخاصة بهم، مما يقلل بشكل مؤكد من التسرب الضار. كما أصبحت أنظمة التبريد بالماء أكثر ذكاءً أيضًا، حيث تمكن العديد من العمليات الرائدة من إعادة تدوير ما يقارب كامل مياه العمليات الخاصة بها في الوقت الراهن، رغم أن الوصول إلى العلامة المثالية البالغة 95 بالمئة لا يزال يتطلب بعض الضبط الدقيق حسب الإعداد الخاص بكل حالة.

الطريق إلى الأمام: تقنية الدرفلة الذكية والخضراء والمتصلة

تشتمل أحدث جيل من معدات الدرفلة الآن على تقنية البلوك تشين لتتبع الجودة طوال سلسلة الإنتاج بأكملها، إلى جانب أنظمة إنترنت الأشياء التي تساعد المصانع المختلفة على التعاون خلال عمليات الصهر والدرفلة والتشطيب. شهدت إحدى التجارب الحديثة في مصنع بألمانيا انخفاضًا في أوقات التسليم بنسبة تقارب 40٪ عند ربط جميع هذه الأنظمة معًا. كما توجد تطورات مثيرة في طرق التشكيل بمساعدة الليزر، والتي قد تقلل من هدر المواد بنحو 22٪، دون المساس بمتطلبات قوة ASTM المهمة. تشير هذه التطورات إلى ما يراه الكثيرون في القطاع القفزة الكبيرة التالية في تصنيع الصلب – مما يجعله ليس أسرع فحسب، بل أفضل أيضًا للشركات والبيئة على المدى الطويل.

الأسئلة الشائعة

ما الفرق الرئيسي بين الدرفلة الساخنة والدرفلة الباردة؟

تُجرى عملية الدرفلة الساخنة عند درجات حرارة عالية، وعادة ما تكون بين 900 إلى 1200 درجة مئوية، وتُستخدم لإنتاج منتجات كمّية كبيرة مثل العوارض على شكل حرف I والقضبان، في حين تُجرى عملية الدرفلة الباردة عند درجة حرارة الغرفة لتحقيق دقة عالية وقوة وتشطيب سطحي أملس، مما يجعلها مثالية لتطبيقات هياكل السيارات والأجهزة الإلكترونية.

ما هي الاستخدامات الشائعة للصلب المدلفن على الساخن؟

يُستخدم الصلب المدلفن على الساخن بشكل شائع في المشاريع الإنشائية الكبيرة مثل الجسور وبناء السفن والتطبيقات الهيكلية الفولاذية نظرًا لفعاليته من حيث التكلفة وسهولة إنتاجه.

كيف تحسّن عملية الدرفلة الباردة خصائص الصلب؟

يُحسِّن التدحرج البارد قوة الفولاذ من خلال التصلب الناتج عن الانفعال، ويعمل على تحسين تشطيب السطح ودقة السمك، مما يجعله مناسبًا للمنتجات التي تتطلب تحملات ضيقة وقوامًا ناعمًا.

ما هي التطورات في تقنية درفلة الصلب؟

تشمل التطورات الحديثة دمج الذكاء الاصطناعي، وإنترنت الأشياء، ونظم الصيانة التنبؤية لتعزيز الكفاءة التشغيلية، وتقليل استهلاك الطاقة، والحد من توقف العمليات، إلى جانب ممارسات مستدامة مثل أنظمة الدفع الاسترجاعية واستخدام مواد تشحيم صديقة للبيئة.

لماذا تُستخدم أجهزة الاستشعار الذكية في الدرافيل الحديثة؟

توفر أجهزة الاستشعار الذكية بيانات فورية حول العمليات، مما يساعد في الصيانة التنبؤية التي تقلل من الأعطال المفاجئة من خلال الكشف المبكر عن الأعطال المحتملة والتدخل السريع.